In today’s HVAC market, Cassette AC Unit air conditioning units have gained significant popularity due to their efficient cooling capabilities and discreet ceiling-mounted design. This comprehensive guide explores everything you need to know about cassette AC units, from their components and working principles to applications, advantages, disadvantages, and more.

Key Components of a Cassette AC Unit

A cassette AC unit is composed of several essential components that work together to provide effective cooling. These components include:

- Evaporator Coil: Located inside the unit, the evaporator coil absorbs heat from indoor air as it passes over the coil’s surface. This process cools the air before it is distributed back into the room.

- Condenser Coil: Situated outside the unit, the condenser coil releases the absorbed heat to the external environment. It plays a crucial role in expelling heat from the refrigerant, allowing the cycle to continue.

- Compressor: The compressor is responsible for pressurizing and circulating the refrigerant throughout the system. By compressing the refrigerant, it increases its temperature, facilitating efficient heat exchange.

- Expansion Valve: This component regulates the flow of refrigerant into the evaporator coil, controlling the rate at which the refrigerant expands and evaporates, thereby managing the cooling process.

- Fan: The fan inside the unit blows air over the evaporator coil and circulates it throughout the room. This airflow ensures even distribution of cooled air, enhancing comfort.

- Air Filters: Cassette AC units are equipped with air filters that trap dust, pollen, and other particles from the circulating air. Clean filters improve indoor air quality and maintain the unit’s efficiency.

- Control Panel: The control panel allows users to adjust settings such as temperature, fan speed, and operating modes. It provides convenient access to the unit’s functionalities.

Each of these components plays a crucial role in the efficient operation of a cassette AC unit, ensuring optimal cooling performance and indoor comfort.

Working Principle of Cassette AC Units

The working principle of a cassette AC unit revolves around the fundamental refrigeration cycle, which involves the continuous circulation of refrigerant to absorb heat from indoor air and release it outdoors. Here’s a simplified explanation of the process:

- Compression: The compressor pressurizes the refrigerant, raising its temperature significantly.

- Condensation: The hot refrigerant moves to the condenser coil, where it releases heat to the external environment and condenses into a high-pressure liquid state.

- Expansion: Passing through the expansion valve, the refrigerant undergoes a pressure drop, causing it to evaporate and absorb heat from indoor air in the evaporator coil.

- Circulation: The fan blows air over the cooled evaporator coil, distributing cooled air throughout the room while the refrigerant continues its cycle to maintain desired indoor temperatures.

This continuous process of compression, condensation, expansion, and circulation enables cassette AC units to effectively cool indoor spaces while maintaining energy efficiency.

Advantages of Cassette AC Units in Commercial Spaces

Cassette AC units offer several advantages that make them particularly suitable for commercial environments:

- Space Efficiency: By mounting flush with the ceiling, cassette AC units conserve valuable floor space that can be utilized for other purposes. This space-saving design is especially beneficial in crowded or compact commercial settings.

- Uniform Air Distribution: These units provide even distribution of cooled air throughout the room, eliminating hot spots and ensuring consistent comfort levels for occupants.

- Aesthetic Appeal: The flush-mounted design of cassette AC units blends seamlessly with interior decor, maintaining the aesthetic appeal of commercial spaces without compromising on cooling efficiency.

- Low Noise Levels: Operating quietly, cassette AC units minimize disruptions in workplaces and commercial settings, creating a conducive environment for productivity and customer satisfaction.

- Adjustable Airflow: Equipped with adjustable louvers, cassette AC units allow users to customize airflow direction according to specific preferences, enhancing comfort and air distribution efficiency.

These features collectively contribute to the popularity of cassette AC units in offices, retail stores, restaurants, and various other commercial establishments where efficient cooling and aesthetic considerations are paramount.

Disadvantages of Cassette AC Units Compared to Other Types

Despite their numerous advantages, cassette AC units also present certain drawbacks that potential users should consider:

- Installation Complexity: Ceiling-mounted installation of cassette AC units can be more complex and labor-intensive compared to other types of AC systems. It requires careful assessment of ceiling structures and may necessitate professional installation services.

- Higher Initial Cost: The initial purchase and installation costs of cassette AC units are generally higher than those of conventional split-system or window AC units. This initial investment may deter budget-conscious consumers.

- Limited Placement Options: Due to their ceiling-mounted configuration, cassette AC units have limited placement flexibility. This restriction may impact their suitability for certain room layouts or architectural designs.

- Maintenance Accessibility: Routine maintenance tasks, such as filter cleaning or coil inspection, may require specialized equipment or professional assistance due to the unit’s elevated position on the ceiling.

While cassette AC units offer efficient cooling and aesthetic benefits, potential users should weigh these disadvantages against their specific requirements and budget constraints.

Common Applications of Cassette AC Units in Building Design

Cassette AC units find widespread application in various building designs and architectural settings:

- Office Buildings: These units are commonly used in office spaces to provide efficient cooling while maintaining a professional and uncluttered environment.

- Hotels: Cassette AC units contribute to guest comfort in hotel rooms and common areas, ensuring a pleasant and relaxing stay for visitors.

- Retail Stores: These units create a comfortable shopping environment for customers, enhancing their shopping experience and encouraging longer visits.

- Restaurants: Cassette AC units help maintain optimal indoor temperatures in dining areas, contributing to a comfortable dining atmosphere for patrons.

- Residential Spaces: In residential settings, cassette AC units are favored for their discreet installation and efficient cooling capabilities, making them suitable for modern home designs.

Their versatility and ability to blend seamlessly with interior aesthetics make cassette AC units a preferred choice among architects, designers, and building owners seeking effective cooling solutions.

Technological Advancements in Cassette AC Units

Recent technological innovations have significantly enhanced the performance and efficiency of cassette AC units:

- Inverter Technology: Many modern cassette AC units incorporate inverter technology, which allows the compressor to operate at variable speeds based on cooling demands. This technology not only improves energy efficiency but also reduces operational noise levels.

- Smart Controls: Integrated smart controls enable users to remotely monitor and adjust the settings of their cassette AC units via mobile devices or applications. This convenience enhances user experience and allows for optimal cooling management.

- Enhanced Air Filters: Advanced air filtration systems within cassette AC units effectively capture dust, allergens, and airborne particles, thereby improving indoor air quality and promoting healthier environments.

- Energy-Saving Features: Cassette AC units are equipped with energy-saving modes and features that optimize performance while reducing energy consumption during off-peak hours or low cooling demands.

These technological advancements underscore ongoing efforts to make cassette AC units more energy-efficient, user-friendly, and environmentally sustainable.

Differences Between Cassette AC Units and Other Types

Cassette AC units differ from traditional split-system or window AC units in several key aspects:

- Installation: Cassette AC units are typically installed in the ceiling, whereas split-system AC units consist of separate indoor and outdoor components that are wall-mounted or placed on the ground.

- Air Distribution: Cassette AC units feature 360-degree airflow distribution, ensuring uniform cooling throughout the room. In contrast, split-system AC units provide directional airflow from wall-mounted indoor units.

- Noise Levels: Due to their ceiling-mounted installation, cassette AC units operate quietly compared to split-system units, which may generate noise from outdoor compressors or indoor fans.

- Aesthetic Considerations: Cassette AC units blend discreetly with interior decor, offering a seamless appearance that complements modern architectural designs. In contrast, split-system AC units may feature visible indoor and outdoor components that impact visual aesthetics.

Understanding these differences helps consumers choose the most suitable AC unit based on their specific cooling needs, space requirements, and aesthetic preferences.

Choosing the Right Size Cassette AC Unit for Your Room

Selecting the appropriate size of a cassette AC unit is crucial to ensure optimal cooling efficiency and performance:

- Room Size: Measure the dimensions of the room where the AC unit will be installed to determine its cooling capacity requirements.

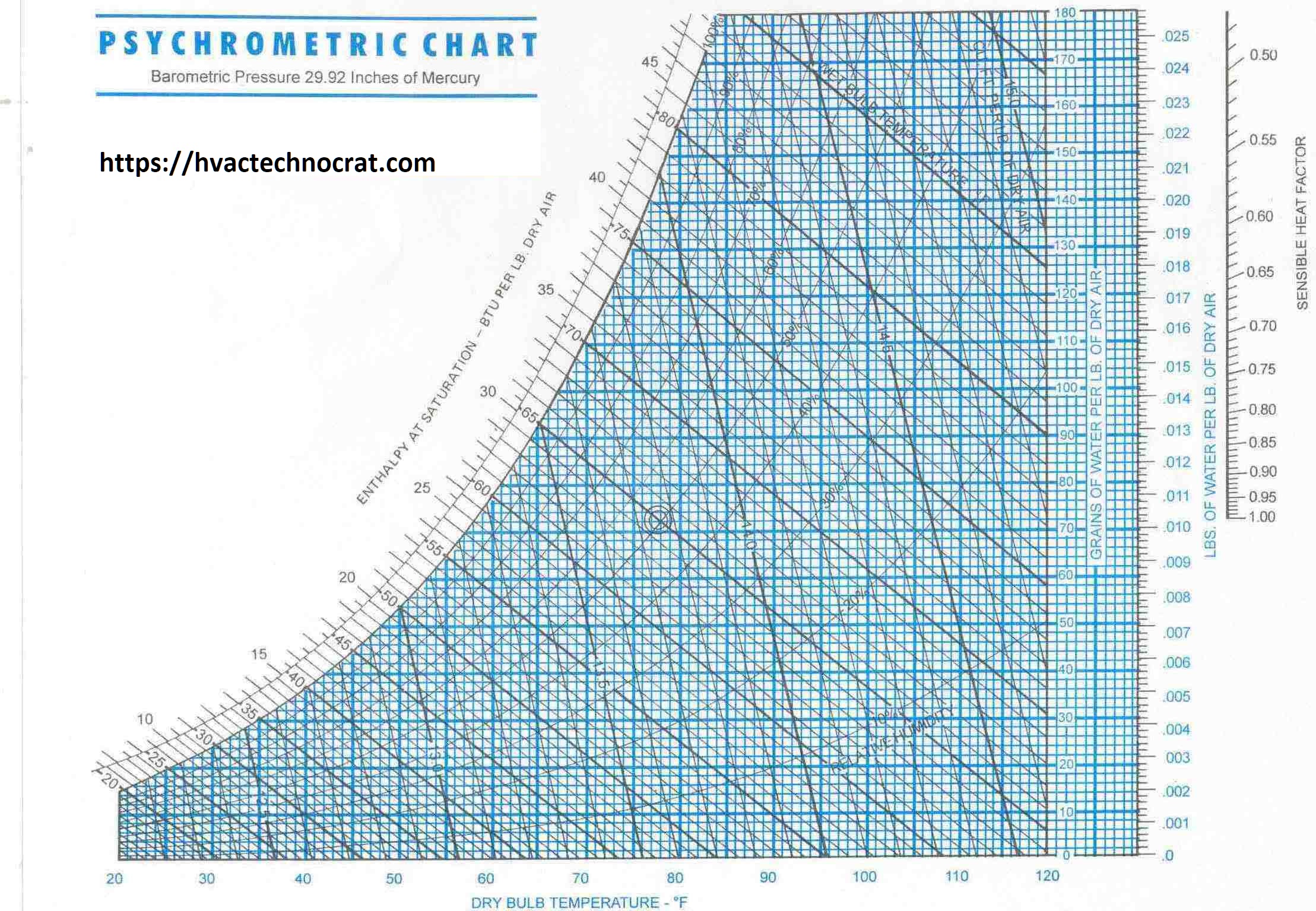

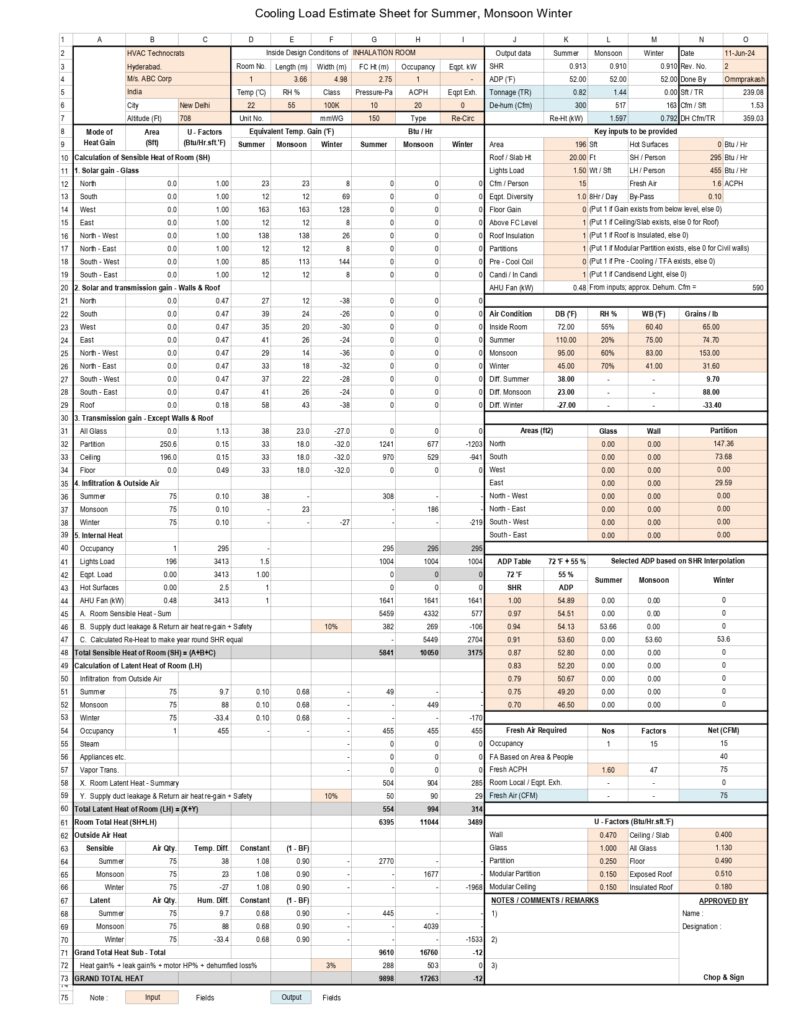

- Heat Load Calculation: Conduct a heat load calculation to assess factors such as room orientation, insulation levels, and heat-generating equipment.

- Manufacturer Guidelines: Refer to the manufacturer’s recommendations regarding the ideal cooling capacity (BTU) based on room size and environmental conditions.

Choosing an appropriately sized cassette AC unit prevents underperformance or overloading, ensuring efficient cooling and energy savings over the unit’s lifespan.

Impact of Airflow Pattern on Cassette AC Unit Performance

The airflow pattern of a cassette AC unit significantly influences its cooling effectiveness and comfort levels:

- 360-Degree Air Distribution: Cassette AC units distribute cooled air evenly in all directions, minimizing temperature variations and ensuring consistent comfort throughout the room.

- Adjustable Louvers: The unit’s adjustable louvers allow users to control the direction and spread of airflow, optimizing cooling performance based on room layout and occupant preferences.

- Indoor Air Circulation: Efficient indoor air circulation reduces stagnant air pockets and enhances ventilation, contributing to improved indoor air quality and occupant comfort.

Understanding and optimizing airflow patterns enhances the overall efficiency and performance of cassette AC units, ensuring optimal cooling and comfort in commercial and residential spaces.

Role of Cassette AC Units in Improving Indoor Air Quality

Cassette AC units play a crucial role in enhancing indoor air quality (IAQ) through effective filtration and ventilation:

- Advanced Filtration Systems: Built-in air filters capture airborne particles, dust, pollen, and allergens, preventing them from circulating in indoor spaces and improving IAQ.

- Continuous Ventilation: The circulation of fresh, filtered air reduces humidity levels and removes stale air, creating a healthier and more comfortable indoor environment.

- IAQ Monitoring: Some cassette AC units feature IAQ sensors that monitor air quality parameters and adjust operation settings accordingly to maintain optimal IAQ levels.

By promoting cleaner and fresher indoor air, cassette AC units contribute to occupant well-being, productivity, and overall comfort in both residential and commercial settings.

Role of Cassette AC Units in Energy Conservation

Cassette AC units incorporate several energy-saving features and technologies to promote efficient cooling and reduce electricity consumption:

- Inverter Technology: Inverter-driven compressors adjust operating speeds based on cooling demands, minimizing energy usage and optimizing performance.

- Energy-Efficient Modes: These units offer programmable modes such as eco mode or sleep mode, which adjust cooling settings to conserve energy during periods of low activity or occupancy.

- Smart Controls: Integrated smart controls enable remote monitoring and scheduling, allowing users to manage cooling operations efficiently and avoid unnecessary energy consumption.

By combining these energy-efficient technologies, cassette AC units help reduce operational costs and environmental impact while ensuring reliable and sustainable cooling performance.

Types of Cassette AC Units Available in the Market

Cassette AC units are available in various types and configurations to suit different cooling requirements and installation preferences:

- Single Zone Units: Designed to cool a single room or area, these units are ideal for residential applications or smaller commercial spaces.

- Multi-Zone Units: These systems consist of multiple indoor units connected to a single outdoor unit, providing customized cooling solutions for larger areas or multiple rooms.

- Heat Pump Units: Some cassette AC units are equipped with heat pump technology, allowing them to provide both cooling and heating functions for year-round comfort.

- Ducted Cassette Units: These units feature ducted airflow systems that distribute cooled air through ductwork, offering enhanced flexibility and installation options.

Choosing the right type of cassette AC unit depends on factors such as cooling capacity, installation requirements, and specific operational needs.

Comparison Between Ceiling-Mounted and Wall-Mounted Cassette AC Units

Cassette AC units are available in ceiling-mounted and wall-mounted configurations, each offering unique advantages:

- Ceiling-Mounted Units: These units are installed flush with the ceiling, providing discreet and unobtrusive cooling without occupying floor space. They offer 360-degree airflow distribution for consistent comfort.

- Wall-Mounted Units: Wall-mounted cassette AC units are installed on interior walls, offering flexibility in placement and installation. They provide directional airflow and are suitable for rooms with specific cooling needs.

Choosing between ceiling-mounted and wall-mounted cassette AC units depends on room layout, aesthetic preferences, and cooling requirements.

Cassette AC units are well-suited for various types of buildings and spaces, including:

- Office Buildings: These units provide efficient cooling for individual offices, conference rooms, and open-plan areas, maintaining comfortable working environments.

- Retail Stores: Cassette AC units offer discreet cooling solutions for retail spaces, ensuring pleasant shopping experiences for customers and staff.

- Hotels: These units contribute to guest comfort in hotel rooms, lobbies, and common areas, enhancing overall guest satisfaction.

- Restaurants: Cassette AC units help maintain optimal temperatures in dining areas, ensuring a pleasant dining experience for patrons.

- Residential Spaces: In homes, cassette AC units provide efficient cooling with minimal visual impact, blending seamlessly with interior decor.

Their versatility, efficiency, and aesthetic appeal make cassette AC units a preferred choice among architects, designers, and building owners seeking effective cooling solutions.

Integration of Cassette AC Units into Residential Spaces

In residential settings, cassette AC units offer several advantages that cater to modern living requirements:

- Discreet Installation: Ceiling-mounted cassette units blend seamlessly with interior aesthetics, maintaining unobtrusive cooling without occupying valuable floor space.

- Efficient Cooling: These units provide effective cooling for living rooms, bedrooms, and other areas, ensuring comfort during hot weather.

- Quiet Operation: Cassette AC units operate quietly, minimizing noise disruptions and enhancing overall indoor comfort for residents.

- Energy Efficiency: Modern cassette units incorporate energy-saving features that reduce operational costs and environmental impact, making them cost-effective solutions for homeowners.

By integrating cassette AC units into residential spaces, homeowners can enjoy enhanced comfort, improved indoor air quality, and energy-efficient cooling throughout the year.

Key Specifications to Consider When Choosing a Cassette AC Unit

When selecting a cassette AC unit, it’s essential to evaluate key specifications to ensure optimal performance and suitability:

- Cooling Capacity (BTU): This specification indicates the unit’s cooling power and should be matched to the size of the room or area being cooled.

- Energy Efficiency Ratio (EER): The EER reflects the unit’s energy efficiency by comparing cooling output to energy input. Higher EER ratings indicate greater efficiency.

- Noise Levels: Consider the unit’s noise output, typically measured in decibels (dB). Quieter units are preferable for noise-sensitive environments.

- Dimensions: Ensure the unit’s dimensions are compatible with ceiling space and installation requirements, allowing for proper fit and ventilation.

- Warranty Coverage: Review the manufacturer’s warranty terms, including coverage duration and conditions, to ensure comprehensive protection against potential defects or malfunctions.

By considering these specifications, consumers can make informed decisions and select a cassette AC unit that meets their cooling needs effectively.

Interpreting Specifications Listed for Cassette AC Units

Understanding and interpreting the specifications listed for cassette AC units is essential for assessing their performance and suitability:

- Cooling Capacity: This specification indicates the amount of heat the unit can remove from indoor air within a specific time, expressed in BTU (British Thermal Units) per hour.

- Energy Efficiency Ratio (EER): The EER represents the cooling output divided by the electrical input, providing a measure of the unit’s energy efficiency. Higher EER ratings indicate lower energy consumption.

- Noise Levels: Manufacturers typically specify noise levels in decibels (dB) to indicate the unit’s operational sound output. Lower dB ratings denote quieter operation.

- Dimensions and Weight: These specifications detail the unit’s physical size and weight, ensuring compatibility with ceiling space and installation requirements.

- Additional Features: Specifications may include features such as adjustable airflow louvers, programmable settings, remote control capabilities, and advanced filtration systems.

By carefully reviewing and interpreting these specifications, consumers can make informed choices and select a cassette AC unit that aligns with their cooling requirements and preferences.

Benefits of Investing in Cassette AC Units for Businesses

Businesses can benefit significantly from investing in cassette AC units due to their unique advantages and operational efficiency:

- Enhanced Comfort: Cassette AC units provide effective cooling and temperature control, creating a comfortable environment for employees, customers, and visitors.

- Improved Aesthetics: The sleek, flush-mounted design of cassette units enhances interior aesthetics and contributes to a professional and inviting business environment.

- Energy Efficiency: Modern cassette units feature energy-saving technologies that reduce operational costs and promote sustainable business practices.

- Noise Reduction: These units operate quietly, minimizing disruptions in workplaces and ensuring a conducive environment for productivity and concentration.

- Flexible Installation: Cassette AC units offer flexibility in installation, adapting to various commercial settings and optimizing space utilization.

By investing in cassette AC units, businesses can enhance operational efficiency, improve indoor comfort, and create positive impressions on customers and stakeholders.

Preference for Other AC Unit Types Over Cassette Models

While cassette AC units offer several advantages, some users may prefer alternative AC unit types for specific reasons:

- Cost Considerations: Other AC unit types, such as split-system or window units, may have lower initial purchase and installation costs, making them more budget-friendly options for consumers.

- Installation Flexibility: Split-system AC units offer flexible installation options, including wall-mounting or floor-standing configurations, which may better suit certain room layouts or building designs.

- Personal Preferences: Individual preferences for AC unit aesthetics, noise levels, or specific cooling requirements may influence users’ choices of alternative AC unit types over cassette models.

Understanding these considerations helps users evaluate and select the most suitable AC unit type based on their priorities, budget constraints, and operational preferences.

Importance of Technical Data Sheets for Cassette AC Units

Technical data sheets provide vital information that helps consumers and HVAC professionals assess the performance, specifications, and capabilities of cassette AC units:

- Performance Metrics: Data sheets include cooling capacity, EER ratings, noise levels, and airflow specifications, enabling precise evaluation of the unit’s operational efficiency.

- Installation Requirements: Information on dimensions, weight, and installation guidelines ensures compatibility with ceiling space and structural considerations.

- Maintenance Guidelines: Data sheets may outline recommended maintenance procedures, filter replacement schedules, and troubleshooting tips to optimize unit performance and longevity.

- Warranty Coverage: Details on warranty terms and conditions provide assurance of product quality and comprehensive protection against potential defects.

By reviewing technical data sheets, consumers can make informed decisions, address installation challenges, and ensure efficient operation and maintenance of cassette AC units.

Information to Look for in a Cassette AC Unit’s Technical Data Sheet

When reviewing a cassette AC unit’s technical data sheet, focus on critical information that influences performance, efficiency, and compatibility:

- Cooling Capacity: Verify the unit’s BTU rating to determine its cooling power and suitability for specific room sizes or environments.

- Energy Efficiency Ratings: Evaluate EER or SEER ratings to assess the unit’s energy efficiency and potential cost savings over its operational lifespan.

- Noise Levels: Check dB ratings to understand the unit’s operational sound output and its impact on indoor noise levels.

- Dimensions and Installation Requirements: Ensure the unit’s dimensions and installation guidelines align with ceiling space and structural considerations for seamless integration.

- Additional Features and Technologies: Review specifications for advanced features such as inverter technology, smart controls, and enhanced filtration systems to optimize cooling performance and user experience.

By focusing on these key aspects in the technical data sheet, consumers can confidently select a cassette AC unit that meets their cooling requirements, operational preferences, and budget considerations.

Primary Components of a Cassette AC Unit and Their Efficiency Contributions

The primary components of a cassette AC unit work together to ensure efficient cooling performance:

- Evaporator Coil: This component absorbs heat from indoor air, cooling it before circulating it back into the room. A clean and well-maintained evaporator coil enhances cooling efficiency.

- Condenser Coil: Responsible for releasing absorbed heat to the external environment, the condenser coil plays a crucial role in the refrigeration cycle’s heat exchange process.

- Compressor: The compressor pressurizes and circulates refrigerant through the system, maintaining optimal pressure and temperature levels for efficient heat transfer.

- Expansion Valve: This component regulates refrigerant flow into the evaporator coil, controlling the rate of evaporation and ensuring precise cooling capacity.

- Fan: The fan circulates air over the evaporator coil and throughout the room, distributing cooled air evenly and enhancing overall cooling efficiency.

- Filters: Air filters trap dust, pollen, and other airborne particles, preventing them from entering the system and maintaining indoor air quality.

- Control Panel: User-friendly controls allow for easy adjustment of settings such as temperature, fan speed, and operating modes, optimizing comfort and energy efficiency.

Each of these components plays a critical role in the functionality and efficiency of a cassette AC unit, ensuring reliable cooling performance and indoor comfort.

Factors Influencing the Design of Cassette AC Units

The design of cassette AC units is influenced by several factors that cater to functional performance, installation requirements, and user preferences:

- Ceiling Space: Units are designed to fit seamlessly within standard ceiling grids, maximizing space utilization while maintaining aesthetic appeal.

- Installation Flexibility: Manufacturers offer various installation options, including recessed, semi-recessed, or surface-mounted configurations, to accommodate diverse architectural designs.

- Cooling Efficiency: Design considerations focus on optimizing airflow distribution, heat exchange capabilities, and refrigerant management for enhanced cooling efficiency.

- Noise Reduction: Innovative designs incorporate noise-reducing technologies and vibration dampeners to minimize operational noise levels and enhance user comfort.

- User Experience: Ergonomic features such as remote controls, programmable settings, and smart connectivity enhance user convenience and operational flexibility.

By addressing these design factors, cassette AC units deliver superior performance, energy efficiency, and user satisfaction across various residential and commercial applications.

Evolution of Cassette AC Unit Design Over the Years

The design of cassette AC units has evolved significantly to meet changing consumer demands and technological advancements:

- Sleek Aesthetics: Modern units feature streamlined profiles, flush-mounted designs, and minimalist aesthetics that blend seamlessly with contemporary interior decor.

- Enhanced Cooling Performance: Advanced technologies, such as inverter compressors and enhanced airflow systems, improve cooling efficiency and operational reliability.

- Energy Efficiency: Innovations in energy-saving features and smart controls optimize performance while reducing operational costs and environmental impact.

- Improved Air Quality: Integrated air filtration systems and IAQ enhancements promote cleaner, healthier indoor environments for enhanced occupant comfort.

- Noise Reduction: Design refinements focus on minimizing operational noise levels, ensuring quiet operation and minimal disruption in residential and commercial settings.

By embracing these design advancements, cassette AC units continue to redefine cooling solutions, offering superior comfort, efficiency, and aesthetic appeal for modern living and working environments.

Installation Process of Cassette AC Units in Commercial Settings

The installation of cassette AC units in commercial settings involves several systematic steps to ensure optimal performance and operational efficiency:

- Site Assessment: Conduct a thorough assessment of the installation site, considering ceiling structure, electrical requirements, and access for equipment and personnel.

- Unit Placement: Determine the optimal location for unit placement, considering airflow distribution, aesthetic considerations, and accessibility for maintenance.

- Ceiling Preparation: Prepare the ceiling space for unit installation, including cutting the appropriate opening, reinforcing structural support if necessary, and ensuring proper alignment.

- Electrical Installation: Connect the unit to the electrical supply, following manufacturer specifications and local building codes to ensure safe and compliant operation.

- Refrigerant Line Connection: Install and connect refrigerant lines between the indoor and outdoor units, ensuring proper sealing, insulation, and compliance with refrigeration regulations.

- Testing and Commissioning: Conduct comprehensive testing of the unit’s functionality, including airflow, temperature control, and operational modes, to verify performance and address any issues.

- User Training: Provide training to facility personnel on unit operation, maintenance procedures, and troubleshooting techniques to ensure optimal performance and longevity.

By following these installation processes and best practices, commercial facilities can achieve efficient and reliable operation of cassette AC units, enhancing indoor comfort and occupant satisfaction.

Maintenance Tips for Maximizing the Lifespan of Cassette AC Units

Regular maintenance is essential for maximizing the lifespan and efficiency of cassette AC units:

- Filter Cleaning or Replacement: Clean or replace air filters regularly to maintain optimal airflow and prevent dust buildup that can affect cooling performance.

- Coil Cleaning: Schedule routine cleaning of evaporator and condenser coils to remove dirt, debris, and contaminants that hinder heat exchange efficiency.

- Refrigerant Check: Monitor refrigerant levels and perform leak checks to ensure proper system operation and prevent potential compressor damage.

- Fan Inspection: Check fan blades for debris or obstructions and ensure smooth operation to maintain efficient airflow distribution.

- Condensate Drainage: Clear condensate drains to prevent clogs and water buildup that can lead to moisture-related issues and system malfunctions.

- Electrical Components: Inspect electrical connections, controls, and wiring for signs of wear or corrosion, ensuring safe and reliable operation.

- Professional Service: Schedule annual maintenance by qualified HVAC technicians to perform comprehensive inspections, adjustments, and performance tuning.

By following these maintenance tips, users can prolong the lifespan of cassette AC units, optimize energy efficiency, and ensure consistent cooling performance for residential and commercial applications.

Common Issues and Troubleshooting Tips for Cassette AC Units

Understanding common issues and troubleshooting tips helps users address potential problems and ensure reliable operation of cassette AC units:

- Inadequate Cooling: Check air filters for clogs and clean or replace them as needed. Ensure adequate airflow around the unit and verify that settings are correct for cooling mode.

- Uneven Air Distribution: Inspect adjustable louvers for obstructions or misalignment. Adjust airflow direction and louvers for optimal air distribution throughout the room.

- Water Leakage: Check condensate drains for blockages and clear them to prevent water buildup. Inspect connections and seals for leaks that may require professional repair.

- Electrical Issues: Verify power supply and electrical connections. Reset circuit breakers or replace fuses if necessary. Consult a qualified technician for complex electrical problems.

- Unusual Noises: Inspect fan blades for debris or damage. Tighten loose components and ensure proper installation to reduce vibration and noise levels.

- Remote Control Malfunctions: Replace remote control batteries and ensure a clear line of sight between the remote and unit’s receiver. Reset or reprogram remote settings as needed.

- Sensor Errors: Clean or recalibrate IAQ sensors to ensure accurate monitoring and adjustment of indoor air quality parameters.

By addressing these common issues promptly and applying troubleshooting tips, users can maintain optimal performance and extend the lifespan of cassette AC units, ensuring consistent comfort and efficiency.

Summary of Cassette AC Unit Advantages and Applications

Cassette AC units offer numerous advantages and versatile applications across residential and commercial settings:

- Advantages: Sleek design, discreet installation, 360-degree airflow distribution, quiet operation, energy efficiency, and advanced features such as inverter technology and smart controls.

- Residential Applications: Ideal for living rooms, bedrooms, kitchens, and other living spaces, providing efficient cooling with minimal visual impact.

- Commercial Applications: Suitable for offices, retail stores, hotels, restaurants, and various commercial spaces, enhancing indoor comfort and operational efficiency.

- Specialized Installations: Options include single-zone and multi-zone configurations, ducted units, and models with heat pump capabilities for year-round comfort.

By leveraging these advantages and applications, cassette AC units deliver superior cooling performance, energy efficiency, and user satisfaction in diverse environments.

Comparison Between Cassette AC Units and Other Types

When comparing cassette AC units with other types of air conditioning systems, several key factors influence consumer preferences and practical considerations:

- Installation: Cassette AC units are typically installed in the ceiling, offering a discreet and space-saving solution. In contrast, split-system AC units may require wall-mounting or floor-standing installations, which can impact interior aesthetics and space utilization.

- Cooling Efficiency: Both cassette and split-system AC units offer efficient cooling performance. Cassette units feature 360-degree airflow distribution, ensuring uniform temperature control throughout the room, while split-system units may vary in airflow direction and distribution based on installation.

- Noise Levels: Cassette AC units are known for their quiet operation, making them suitable for environments where minimal noise disruption is essential. Split-system units vary in noise levels depending on the model and installation location.

- Design Flexibility: Split-system AC units offer flexibility in installation options, accommodating various room layouts and building designs. Cassette units, while ceiling-mounted, provide a sleek and integrated appearance that enhances interior aesthetics.

- Cost Considerations: Initial costs for cassette AC units may include installation and ceiling modifications, depending on existing infrastructure. Split-system units may have lower upfront costs but could incur additional expenses for installation and equipment.

Understanding these differences helps consumers evaluate the most suitable air conditioning solution based on their preferences, budget, and specific cooling requirements.

Technical Data Sheet Importance in Cassette AC Unit Selection

The technical data sheet serves as a crucial tool for selecting the right cassette AC unit by providing comprehensive information on performance, specifications, and operational capabilities:

- Cooling Capacity: Verify the unit’s BTU rating to determine its cooling power and suitability for room size and environmental conditions.

- Energy Efficiency Ratings: Evaluate EER or SEER ratings to assess the unit’s energy efficiency and potential cost savings over its operational lifespan.

- Noise Levels: Check dB ratings to understand the unit’s operational sound output and its impact on indoor noise levels.

- Dimensions and Installation Requirements: Ensure the unit’s dimensions and installation guidelines align with ceiling space and structural considerations for seamless integration.

- Additional Features and Technologies: Review specifications for advanced features such as inverter technology, smart controls, and enhanced filtration systems to optimize cooling performance and user experience.

By leveraging the information provided in the technical data sheet, consumers can make informed decisions, address installation challenges, and ensure efficient operation and maintenance of cassette AC units.

Primary Components of Cassette AC Units and Their Efficiency Contributions

The efficiency and performance of cassette AC units depend on several primary components that work together seamlessly:

- Evaporator Coil: Absorbs heat from indoor air, cooling it before circulating it back into the room. A clean and well-maintained evaporator coil enhances cooling efficiency.

- Condenser Coil: Releases absorbed heat to the external environment, crucial for the refrigeration cycle’s heat exchange process.

- Compressor: Pressurizes and circulates refrigerant through the system, maintaining optimal pressure and temperature levels for efficient heat transfer.

- Expansion Valve: Regulates refrigerant flow into the evaporator coil, controlling the rate of evaporation and ensuring precise cooling capacity.

- Fan: Circulates air over the evaporator coil and throughout the room, distributing cooled air evenly and enhancing overall cooling efficiency.

- Filters: Trap dust, pollen, and other airborne particles, preventing them from entering the system and maintaining indoor air quality.

- Control Panel: Allows for easy adjustment of settings such as temperature, fan speed, and operating modes, optimizing comfort and energy efficiency.

Each component plays a critical role in the functionality and efficiency of cassette AC units, ensuring reliable cooling performance and indoor comfort.

Factors Influencing the Design Evolution of Cassette AC Units

The design evolution of cassette AC units is driven by various factors that prioritize functionality, installation requirements, and user preferences:

- Ceiling Space: Units are designed to fit seamlessly within standard ceiling grids, maximizing space utilization while maintaining aesthetic appeal.

- Installation Flexibility: Manufacturers offer various installation options, including recessed, semi-recessed, or surface-mounted configurations, to accommodate diverse architectural designs.

- Cooling Efficiency: Design considerations focus on optimizing airflow distribution, heat exchange capabilities, and refrigerant management for enhanced cooling efficiency.

- Noise Reduction: Innovative designs incorporate noise-reducing technologies and vibration dampeners to minimize operational noise levels and enhance user comfort.

- User Experience: Ergonomic features such as remote controls, programmable settings, and smart connectivity enhance user convenience and operational flexibility.

By addressing these design factors, cassette AC units deliver superior performance, energy efficiency, and user satisfaction across residential and commercial applications.

FAQ

Which AC is better, cassette or split?

The choice between cassette and split AC depends on factors like installation space, aesthetic preferences, and cooling efficiency. Cassette ACs are ideal for spaces where ceiling installation is preferred, offering 360-degree airflow and quiet operation. Split ACs, on the other hand, provide flexibility in installation and are suitable for various room sizes.

What is a Cassette AC Unit?

A Cassette AC Unit is a type of air conditioner designed to be mounted in the ceiling. It distributes conditioned air through a grille, ensuring even airflow across the room. It’s commonly used in commercial spaces and offers a discreet cooling solution.

Do cassette ACs consume more electricity?

Cassette ACs are designed for efficiency, often featuring advanced technologies like inverter compressors that adjust power based on cooling demands. Proper sizing, regular maintenance, and energy-efficient models can help minimize electricity consumption.

What are the disadvantages of cassette air conditioners?

Some drawbacks of cassette air conditioners include higher installation costs due to ceiling modifications, potential maintenance challenges due to ceiling-mounted location, and limited options for DIY maintenance.

Cassette AC unit prices vary based on brand, capacity, features, and installation requirements. Generally, they are priced higher than traditional split systems due to their design and installation complexities.

The price of a cassette AC unit depends on factors such as brand, capacity (tonnage), energy efficiency rating, and additional features like smart controls or inverter technology. Prices typically range higher than wall-mounted split ACs.

Cassette AC Units price in India

In India, cassette AC unit prices vary widely based on factors like brand, tonnage, energy efficiency ratings (BEE star ratings), and local installation costs. Prices can range significantly across different cities and regions.

Cassette AC 1.5 Ton Price

The price of a 1.5-ton cassette AC unit varies based on brand and features but generally falls within a specific range. It’s advisable to compare prices from different suppliers and consider long-term operational costs.

Cassette AC Units India

Cassette AC units are widely used in India, particularly in commercial spaces where efficient cooling and aesthetic integration are priorities. They offer advantages like space-saving installation and quiet operation.

Cassette AC 2 Ton

A 2-ton cassette AC unit is suitable for larger rooms or areas requiring higher cooling capacity. Prices and energy efficiency considerations should be reviewed when selecting the right model for specific cooling needs.

Conclusion

Cassette AC units represent a sophisticated cooling solution that combines efficient performance with aesthetic appeal. Their discreet installation, quiet operation, and advanced features make them ideal for enhancing indoor comfort in both residential and commercial settings. With ongoing technological advancements and design innovations, cassette AC units continue to evolve, offering consumers versatile cooling options that prioritize energy efficiency and user convenience. By understanding the key components, operational principles, advantages, and applications of cassette AC units, consumers can confidently select a cooling solution that meets their specific needs and enhances their living or working environment.

Whether for residential living spaces or commercial establishments, the versatility and efficiency of cassette AC units make them a compelling choice for modern cooling solutions. As technology advances and consumer demands evolve, cassette AC units remain at the forefront of innovative HVAC solutions, ensuring optimal comfort, energy efficiency, and environmental sustainability.

For more information on cassette AC units, their applications, or assistance in selecting the right unit for your needs, contact our HVAC experts today. Discover how cassette AC units can transform your indoor environment with reliable cooling performance and unmatched comfort.

Remember, choosing the right HVAC system is crucial for maintaining indoor comfort and energy efficiency. Invest in a cassette AC unit that not only meets your cooling requirements but also enhances your living or working space with its advanced features and superior performance.

About The Author

Omprakash Ramagiri; as the Founder of HVAC Technocrats, I bring over 18 years of experience as a Mechanical Engineer specializing in HVAC (Central Air-conditioning) for commercial, cleanrooms, data centers, and Petrochemical industries. Throughout my career, I’ve held pivotal roles at companies like TATA Consulting Engineers, MW Zander (for Cleanroom solutions), Bluestar Malaysia, and ETA in Dubai. I’ve managed international HVAC projects and gained valuable exposure in dynamic markets like Dubai and Saudi Arabia. With a passion for excellence and a commitment to innovative solutions, I specialize in designing Class 10K & 100K Cleanrooms for various industries. Connect with me to explore collaborations in HVAC design, project sales, and consultancy. Click to visit the Author’s Linkedin page

Disclaimer: The pictures used are for illustrative purposes only. They may not depict actual products or situations and are meant for educational purposes. Actual products, situations, or outcomes may differ.