In the world of HVAC (Heating, Ventilation, and Air Conditioning) systems, Psychrometry plays a crucial role. It involves the study of air properties and their interactions with moisture, which is fundamental in designing and operating HVAC systems efficiently. This article delves into the basics of Psychrometry, its role in HVAC, various Psychrometric processes, applications, specifications, and much more.

What are the Basics of Psychrometry in HVAC?

Psychrometry, a branch of science dealing with the properties of air-water vapor mixtures, plays a critical role in HVAC (Heating, Ventilation, and Air Conditioning) systems. Understanding psychrometry helps engineers and technicians design, analyze, and optimize HVAC systems to ensure efficient and effective climate control. The fundamental elements of psychrometry include parameters such as temperature, humidity, enthalpy, and dew point, which collectively describe the thermodynamic properties of moist air. In HVAC applications, psychrometry allows for precise control of air quality and comfort levels, which are essential for both residential and commercial environments.

What is the Role of Psychrometry in HVAC Systems?

The role of psychrometry in HVAC systems is multifaceted. It involves the measurement and Humidity Control and Temperature control to achieve desired indoor air conditions. By using psychrometric principles, HVAC professionals can predict how air will behave under various conditions, enabling them to design systems that maintain optimal indoor climates. This includes ensuring proper humidity levels to prevent mold growth, maintaining comfortable temperatures, and ensuring efficient energy use. Psychrometry also helps in diagnosing system issues and optimizing performance by analyzing air properties and their changes through HVAC processes.

What Types of Psychrometric Processes are Used in HVAC?

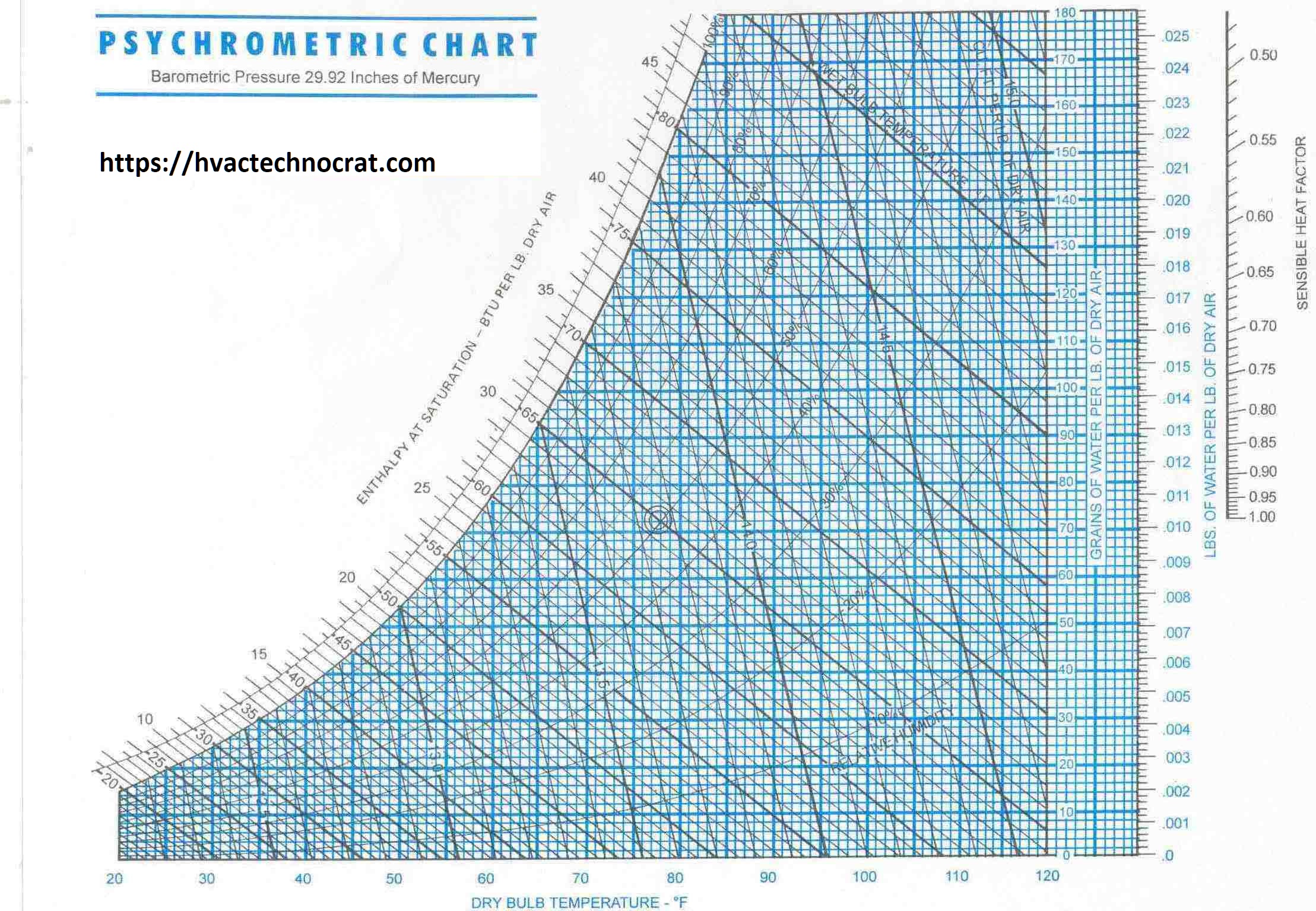

Several psychrometric processes are integral to HVAC systems. These include sensible heating and cooling, where the air temperature is changed without altering its moisture content. Latent heating and cooling involve changes in the moisture content of the air without affecting its temperature. Other processes include humidification, dehumidification, mixing of air streams, and adiabatic cooling. Each process can be plotted and analyzed on a psychrometric chart, providing a visual representation of the air’s condition and helping to determine the necessary changes to achieve desired outcomes in HVAC systems.

Why psychrometry chart in used in HVAC?

The psychrometric chart is essential in HVAC engineering for several reasons:

Understanding Air Properties: It graphically represents thermodynamic properties of moist air, including dry bulb temperature, wet bulb temperature, relative humidity, specific humidity, dew point temperature, and enthalpy. This visualization helps professionals analyze and predict air behavior in various conditions.

Design and Analysis of HVAC Systems: The chart is crucial for designing and analyzing HVAC systems. It allows engineers to determine the conditions for air treatment processes like cooling, heating, humidification, and dehumidification. This aids in accurately assessing air property changes and selecting the right equipment and settings for optimal indoor air quality and thermal comfort.

Energy Efficiency and Optimization: Psychrometric charts help identify opportunities for energy efficiency. By understanding the interactions between temperature and humidity, professionals can optimize heat exchange and moisture control processes, reducing energy consumption and improving system performance.

In summary, the psychrometric chart is vital for visualizing air properties, designing HVAC systems, and enhancing energy efficiency.

What key processes can be marked on a psychrometric chart?

A psychrometric chart visually represents the thermodynamic properties of moist air and illustrates key processes. Sensible heating and cooling processes are depicted as horizontal lines, while humidification and dehumidification are shown as vertical lines. The chart also highlights processes like evaporative cooling and adiabatic mixing, helping engineers to analyze and design HVAC systems effectively. The key processes can be marked on a psychrometric chart, each representing different changes in the air properties. Here is a list of these processes:

- Sensible Heating

- Sensible Cooling

- Humidification

- Dehumidification

- Cooling and Dehumidification

- Heating and Humidification

- Adiabatic Mixing of Two Air Streams

- Evaporative Cooling

- Chemical Dehumidification

- Cooling with Air Washer

- Heating with Steam Injection

- Cooling with Dehumidifier

- Condensation

- Heating and Dehumidification

- Air Mixing (Mixing of Two Air Streams at Different Conditions)

These processes help in understanding and visualizing the changes in air properties such as temperature, humidity, and enthalpy during various HVAC operations.

What are the Applications of Psychrometry in HVAC Design?

Psychrometry has numerous applications in HVAC design. It is used to:

By understanding and applying psychrometric principles, HVAC engineers can create systems that are both efficient and effective, providing optimal indoor environments.

What are the Specifications for Psychrometric Analysis in HVAC?

Psychrometric analysis in HVAC involves several specifications, including:

- Accurate measurement of air properties

- Proper selection of psychrometric charts

- Use of precise calculation methods

- Consideration of environmental factors

- Adherence to industry standards and guidelines

These specifications ensure that psychrometric analysis is reliable and effective, leading to well-designed HVAC systems that meet the desired performance criteria.

What are the Advantages and Disadvantages of Using Psychrometry in HVAC?

Psychrometry offers several advantages in HVAC, including:

- Precise control of indoor climates

- Improved energy efficiency

- Enhanced occupant comfort

- Better air quality management

- Effective troubleshooting and system optimization

However, there are also some disadvantages, such as:

- Complexity in understanding and applying psychrometric principles

- Need for accurate measurements and calculations

- Potential for errors if not properly executed

Despite these challenges, the benefits of using psychrometry in HVAC systems far outweigh the drawbacks, making it an essential aspect of modern HVAC design and operation.

What Information is Typically Included in a Psychrometric Chart?

A psychrometric chart typically includes information on:

- Dry-bulb temperature

- Wet-bulb temperature

- Relative humidity

- Specific humidity

- Dew point temperature

- Enthalpy

- Volume of moist air

This information allows engineers to analyze air properties and make informed decisions about HVAC system design and operation.

What are the Main Parameters Involved in Psychrometric Processes?

The main parameters involved in psychrometric processes include:

- Dry-bulb temperature

- Wet-bulb temperature

- Relative humidity

- Specific humidity

- Dew point temperature

- Enthalpy

These parameters describe the thermodynamic properties of air and are essential for understanding and controlling HVAC systems.

What Inputs are Essential for Psychrometric Analysis in HVAC?

Essential inputs for psychrometric analysis in HVAC include:

- Initial and desired air conditions

- Environmental factors (e.g., outdoor temperature and humidity)

- System specifications (e.g., airflow rates and equipment capacities)

- Load requirements (e.g., heating and cooling loads)

These inputs help engineers accurately analyze and design HVAC systems to meet specific performance criteria.

What Design Considerations are Critical for Psychrometric Processes?

Critical design considerations for psychrometric processes include:

- Accurate measurement of air properties

- Proper selection of psychrometric charts and tools

- Consideration of environmental and load factors

- Adherence to industry standards and guidelines

These considerations ensure that psychrometric analysis is reliable and effective, leading to well-designed HVAC systems.

What Design Parameters are Influenced by Psychrometry?

Design parameters influenced by psychrometry include:

- Heating and cooling loads

- Ventilation rates

- Humidity control requirements

- Energy efficiency measures

- Equipment selection and sizing

By understanding and applying psychrometric principles, HVAC engineers can optimize these parameters to achieve desired performance outcomes.

How are Unit Conversions Handled in Psychrometric Calculations?

Unit conversions in psychrometric calculations are typically handled using conversion factors and formulas. Engineers must ensure that all units are consistent and accurately converted to maintain the integrity of the analysis. Common conversions include temperature (Celsius to Fahrenheit), pressure (Pascals to psi), and energy (Joules to BTUs).

How is Capacity Calculation Performed Using Psychrometric Charts?

Capacity calculation using psychrometric charts involves determining the amount of heating or cooling required to achieve desired air conditions. This is done by plotting the initial and desired air states on the chart and analyzing the processes needed to transition between these states. The chart provides a visual representation of the energy changes involved, allowing engineers to calculate the necessary capacity for HVAC equipment.

What Codes and Standards Govern Psychrometric Analysis in HVAC?

Several codes and standards govern psychrometric analysis in HVAC, including:

- ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) standards

- ISO (International Organization for Standardization) standards

- Local and national building codes

These standards ensure that psychrometric analysis is conducted in a consistent and reliable manner, leading to safe and effective HVAC system design and operation.

What is Included in a Psychrometry Chart?

A psychrometry chart includes

:

- Dry-bulb temperature lines

- Wet-bulb temperature lines

- Relative humidity curves

- Specific humidity lines

- Dew point temperature lines

- Enthalpy lines

- Volume of moist air lines

This comprehensive representation of air properties helps engineers analyze and design HVAC systems.

How is a Psychrometric Chart Created?

A psychrometric chart is created by plotting the relationships between various air properties on a graph. This involves drawing lines for dry-bulb temperature, wet-bulb temperature, relative humidity, specific humidity, dew point temperature, enthalpy, and volume of moist air. The chart is typically developed using empirical data and mathematical models to accurately represent the thermodynamic properties of moist air.

What are the Leading Software Tools Available for Psychrometric Analysis?

Leading software tools for psychrometric analysis include:

- ASHRAE’s Psychrometric Analysis Tool

- Carrier’s HVAC System Design Software

- Trane’s TRACE 700

- Elite Software’s PsyChart

These tools provide advanced features for analyzing air properties, designing HVAC systems, and optimizing performance based on psychrometric principles.

What Should be Included in Design Checklists for Psychrometric Calculation?

Design checklists for psychrometric calculation should include:

- Accurate measurement of air properties

- Selection of appropriate psychrometric charts and tools

- Consideration of environmental and load factors

- Adherence to industry standards and guidelines

- Documentation of all calculations and assumptions

These checklists ensure that psychrometric analysis is conducted accurately and reliably, leading to effective HVAC system design.

What Supporting Details are Necessary for Accurate Psychrometric Analysis?

Supporting details necessary for accurate psychrometric analysis include:

- Accurate measurements of air properties

- Detailed information on environmental conditions

- Comprehensive data on system specifications and load requirements

- Use of reliable psychrometric charts and tools

These details ensure that psychrometric analysis is precise and reliable, leading to effective HVAC system design and operation.

What Procedures are Recommended for Psychrometric Systems?

Recommended procedures for psychrometric systems include:

- Regular calibration and maintenance of measurement instruments

- Accurate measurement and documentation of air properties

- Use of standardized psychrometric charts and tools

- Adherence to industry standards and guidelines

- Continuous monitoring and optimization of system performance

These procedures ensure that psychrometric systems operate efficiently and effectively, maintaining desired indoor climates and energy efficiency.

How is Performance Monitoring Carried Out in Systems Utilizing Psychrometry?

Performance monitoring in systems utilizing psychrometry involves:

- Regular measurement of air properties

- Continuous comparison of measured values with desired conditions

- Use of sensors and data logging equipment

- Analysis of system performance data

- Implementation of corrective actions as needed

By monitoring performance, engineers can ensure that HVAC systems operate efficiently and effectively, maintaining optimal indoor climates.

How is Lifecycle Analysis Performed for Systems Involving Psychrometry?

Lifecycle analysis for systems involving psychrometry includes:

- Evaluation of system performance over time

- Assessment of energy consumption and efficiency

- Analysis of maintenance and operational costs

- Consideration of environmental impacts

- Identification of opportunities for improvement

By conducting lifecycle analysis, engineers can optimize HVAC systems for long-term performance and sustainability.

What Energy Efficiency Measures are Relevant to Psychrometric Processes?

Energy efficiency measures relevant to psychrometric processes include:

- Optimizing system design to reduce energy consumption

- Implementing advanced control strategies

- Regular maintenance and calibration of equipment

- Use of energy-efficient components and materials

- Monitoring and optimizing system performance

These measures help to reduce energy consumption and enhance the efficiency of HVAC systems, contributing to sustainability and cost savings.

How Can Systems be Upgraded or Retrofitted to Improve Psychrometric Performance?

Systems can be upgraded or retrofitted to improve psychrometric performance by:

- Replacing outdated components with energy-efficient alternatives

- Implementing advanced control strategies

- Enhancing insulation and sealing to reduce energy losses

- Regular maintenance and calibration of equipment

- Monitoring and optimizing system performance

These upgrades and retrofits can significantly improve the efficiency and effectiveness of HVAC systems, ensuring optimal indoor climates and energy savings.

What is the Environmental Impact of Using Psychrometric Analysis in HVAC?

The environmental impact of using psychrometric analysis in HVAC includes:

By optimizing HVAC systems using psychrometric analysis, engineers can contribute to environmental sustainability and reduce the overall impact of building operations.

What Safety Factor Considerations are Necessary for Psychrometric Processes?

Safety factor considerations for psychrometric processes include:

- Ensuring accurate measurement and calculation of air properties

- Adherence to industry standards and guidelines

- Regular maintenance and calibration of equipment

- Monitoring system performance and implementing corrective actions as needed

- Consideration of environmental and load factors

These considerations ensure that psychrometric processes are safe and reliable, leading to well-designed and effective HVAC systems.

FAQ

What do you mean by psychrometry?

Psychrometry is the study of the properties of air-water vapor mixtures, crucial for understanding and controlling indoor climates in HVAC systems. It involves parameters like temperature, humidity, enthalpy, and dew point.

What is the psychometric process?

The psychrometric process involves analyzing and manipulating the properties of air, such as temperature and humidity, to achieve desired indoor conditions. This includes processes like heating, cooling, humidification, and dehumidification.

What is the use of a psychrometer?

A psychrometer is an instrument used to measure the moisture content in the air, typically involving dry-bulb and wet-bulb thermometers. It helps determine relative humidity and other psychrometric properties.

What are the applications of psychrometry?

Applications of psychrometry include HVAC system design, environmental control in industrial processes, agricultural applications, and ensuring indoor air quality and comfort in residential and commercial buildings.

Psychrometry ppt

A psychrometry PowerPoint presentation typically includes an overview of psychrometric principles, applications in HVAC systems, and examples of psychrometric charts and processes. It serves as an educational tool for understanding psychrometry in HVAC design.

Psychrometric chart

A psychrometric chart is a graphical representation of the thermodynamic properties of moist air, used to analyze air conditioning processes. It includes parameters like temperature, humidity, and enthalpy, helping engineers design and optimize HVAC systems.

Psychrometry properties

Psychrometric properties include dry-bulb temperature, wet-bulb temperature, relative humidity, specific humidity, dew point temperature, and enthalpy. These properties describe the state of air-water vapor mixtures and are essential for HVAC analysis.

Psychrometric calculator

A psychrometric calculator is a tool, often software-based, that calculates the properties of air-water vapor mixtures. It helps engineers determine parameters like relative humidity, dew point, and enthalpy based on input conditions.

Psychrometry pronunciation

Psychrometry is pronounced as “sy-krom-i-tree,” with emphasis on the second syllable. It combines the Greek words “psyche” (air) and “metron” (measure).

Psychrometric chart meaning

The psychrometric chart represents the properties of moist air and their relationships

. It helps visualize and analyze processes like heating, cooling, humidification, and dehumidification in HVAC systems.

Psychrometric chart metric

A psychrometric chart in metric units uses Celsius for temperature and grams of water per kilogram of dry air for specific humidity. It is used internationally for HVAC analysis and design.

Psychrometric chart download

Psychrometric charts can be downloaded from various sources, including HVAC software providers and industry organizations like ASHRAE. These charts are available in both metric and imperial units.

Psychrometric chart online

Online psychrometric charts are interactive tools available on websites and software platforms. They allow users to input conditions and visualize air properties and processes dynamically.

Printable Psychrometric chart

Printable psychrometric charts are static versions available for download and printing. They provide a handy reference for engineers and technicians working on HVAC systems, helping with on-site analysis and design.

Conclusion

Psychrometry is a fundamental aspect of HVAC system design and operation, providing essential insights into the properties of air-water vapor mixtures. By understanding and applying psychrometric principles, engineers can design efficient and effective HVAC systems that ensure optimal indoor climates, energy efficiency, and occupant comfort. The use of psychrometric charts, advanced software tools, and adherence to industry standards and guidelines are crucial for accurate psychrometric analysis. Despite the complexities involved, the benefits of psychrometry in HVAC far outweigh the challenges, making it an indispensable tool for modern climate control and environmental management.

About The Author

Omprakash Ramagiri; as the Founder of HVAC Technocrats, I bring over 18 years of experience as a Mechanical Engineer specializing in HVAC (Central Air-conditioning) for commercial, cleanrooms, data centers, and Petrochemical industries. Throughout my career, I’ve held pivotal roles at companies like TATA Consulting Engineers, MW Zander (for Cleanroom solutions), Bluestar Malaysia, and ETA in Dubai. I’ve managed international HVAC projects and gained valuable exposure in dynamic markets like Dubai and Saudi Arabia. With a passion for excellence and a commitment to innovative solutions, I specialize in designing Class 10K & 100K Cleanrooms for various industries. Connect with me to explore collaborations in HVAC design, project sales, and consultancy. Click to visit the Author’s Linkedin page

Disclaimer: The pictures used are for illustrative purposes only. They may not depict actual products or situations and are meant for educational purposes. Actual products, situations, or outcomes may differ.