When it comes to cooling your home efficiently, a central AC for home is often the go-to solution. This system not only ensures uniform cooling across all rooms but also enhances indoor air quality by filtering out dust and allergens. Whether you live in a bustling city like Mumbai or a quieter suburban area, understanding how a central AC works and its benefits can help you make an informed decision. Let’s dive into everything you need to know about central AC systems for homes.

How Does a Central AC For Home Works?

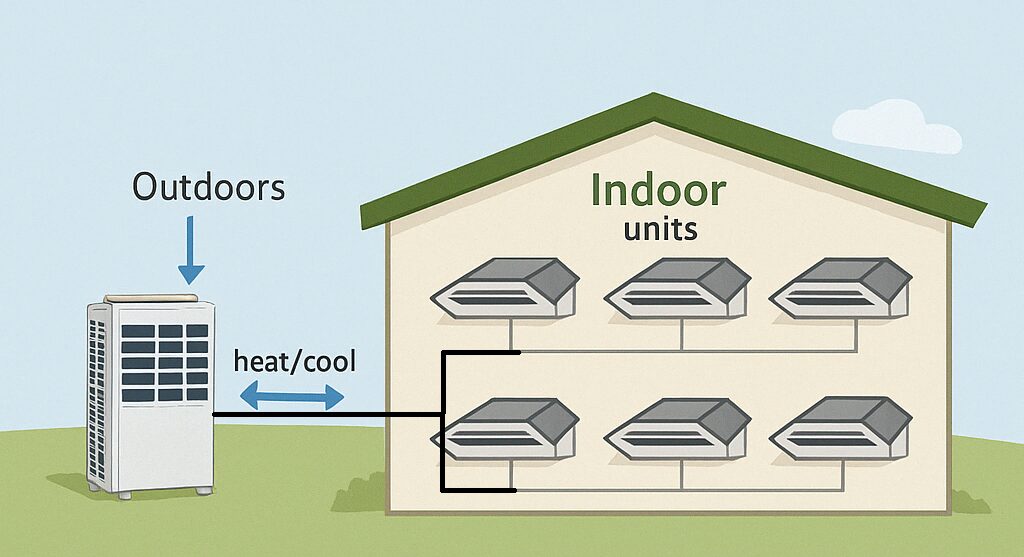

A central AC for home operates by circulating cool air through a network of ducts installed within your house. The process begins with the compressor, which pressurizes the refrigerant and sends it to the evaporator coil located inside the air handler. Here, warm air from your home passes over the cold coil, cooling it down before it’s distributed back into the rooms via vents.

Unlike window units or split systems, central AC provides consistent cooling without creating hot and cold spots. For instance, a homeowner in Hyderabad reported a 25% improvement in comfort after switching to a central AC system, thanks to its ability to maintain stable temperatures throughout the day.

Benefits of Installing a Central AC For Home

Enhanced Comfort Levels

One of the standout advantages of a central AC for home is its ability to deliver even cooling. Unlike portable units that may struggle to reach certain areas, central AC ensures every corner of your house stays comfortable during peak summer months.

Energy Efficiency

Modern central AC systems are designed with energy efficiency in mind. By integrating smart thermostats like these, you can program temperature settings based on your daily routine, reducing unnecessary energy consumption. According to ISHRAE guidelines, this approach can save up to ₹10,000 annually on electricity bills.

Improved Air Quality

Central AC systems come equipped with advanced filtration mechanisms that trap pollutants such as pollen, pet dander, and smoke particles. This feature is particularly beneficial for families with members suffering from allergies or respiratory issues.

Key Considerations Before Buying a Central AC For Home

Before investing in a central AC for home, there are several factors to consider. First, evaluate the size of your property and calculate the required cooling capacity using BTU metrics. You can refer to our detailed guide on heat load calculations here for more insights.

Additionally, ensure your home has adequate ductwork to support the installation. If not, retrofitting might be necessary, which could add to the overall cost. A case study from Pune highlights how proper planning reduced installation expenses by nearly 15%.

Maintenance Tips for Longevity

Proper maintenance plays a crucial role in extending the lifespan of your central AC system. Regular servicing—such as cleaning filters, checking refrigerant levels, and inspecting ducts—can prevent costly repairs. For example, a family in Chennai avoided a ₹50,000 repair bill simply by scheduling annual check-ups.

To learn more about maintaining your air conditioning unit, check out our comprehensive article on AC service near me.

Emerging Trends in Central AC Technology

The HVAC industry is witnessing rapid advancements, especially in residential cooling solutions. AI-driven optimization tools now allow homeowners to monitor and control their central AC systems remotely. Similarly, eco-friendly refrigerants compliant with international standards like ASHRAE and IGBC are becoming increasingly popular.

For those interested in sustainable options, integrating solar panels with your central AC can further reduce carbon footprints while cutting utility costs. Learn more about solar-powered AC units in our dedicated blog post here.

Challenges and Solutions

While central AC systems offer numerous benefits, they aren’t without challenges. High upfront costs and space requirements for ductwork installation are common concerns. However, modular designs and financing options have made these systems more accessible than ever.

Another challenge is ensuring optimal airflow in multi-story homes. To address this, experts recommend zoning techniques where different sections of the house operate independently. For deeper insights, explore our article on zoning strategies for HVAC.

Market Leaders in Central AC for Home: Top Brands and Their Offerings

When it comes to choosing the right air conditioning system for your home, several trusted brands stand out in the market, each offering unique features tailored to different needs.

- Inverter Technology: Known for its advanced inverter technology that ensures energy efficiency and consistent cooling.

- Eco-Friendly Refrigerants: Uses refrigerants with low global warming potential (GWP) to reduce environmental impact.

- Smart Features: Offers smart AC models with Wi-Fi connectivity for remote control via mobile apps.

- Adaptability to Indian Weather: Designs climate solutions tailored to handle diverse Indian weather conditions effectively.

- Affordable Options: Provides budget-friendly models without compromising on performance or durability.

- Wide Range of Products: Offers split, window, and portable air conditioners to suit various customer needs.

- Sleek Design: Combines aesthetic appeal with robust functionality, making it a popular choice for modern homes.

- Advanced Filtration: Equipped with multi-stage filtration systems to improve indoor air quality significantly.

- Customizable Cooling: Allows users to adjust settings for personalized comfort levels.

- AI-Driven Optimization: Incorporates AI technology to enhance energy efficiency and user convenience.

- Quiet Operation: Known for its ultra-quiet models, ideal for bedrooms and offices.

- Durable Components: Builds ACs with high-quality materials to ensure long-term reliability.

- Nanoe Technology: Features nanoe technology for advanced air purification and deodorization.

- Energy Savings: Focuses on developing energy-efficient models to help reduce electricity bills.

- Compact Models: Offers space-saving designs suitable for smaller rooms or apartments.

- Pioneering Legacy: A global leader in HVAC innovation with over a century of expertise.

- Reliable Performance: Trusted for consistent cooling even in extreme temperatures.

- Wide Service Network: Boasts an extensive after-sales service network across India and globally.

Case Study: Transforming Homes with Central AC Systems

In Bengaluru, a leading HVAC consultant helped a residential complex transition to a centralized cooling system. By implementing variable refrigerant flow (VRF) technology, they achieved a 30% reduction in energy usage while improving occupant satisfaction. Such innovations underscore the potential of modern central AC systems to revolutionize home comfort.

FAQs

1. What is the average lifespan of a central AC for home?

Most central AC systems last between 10 to 15 years with regular maintenance.

2. Can I install a central AC if my home doesn’t have ducts?

Yes, ductless mini-split systems serve as excellent alternatives.

3. How much does it cost to install a central AC in India?

Prices vary depending on the brand and size, ranging from ₹2 lakhs to ₹5 lakhs.

4. Are central AC systems noisy?

No, modern systems operate quietly, with noise levels below 40 decibels.

5. Is it possible to integrate smart features with a central AC?

Absolutely! Smart thermostats enable remote control and automation.

6. Do central AC systems improve indoor air quality?

Yes, they filter out airborne contaminants, enhancing overall air purity.

Disclaimer:

Some links in this article are affiliate links, such as those for Amazon products. These may generate a small commission at no extra cost to you, supporting our work. We never compromise editorial integrity for partnerships.

About the Author

Mr. Om Prakash, with over 18 years of hands-on experience in the HVAC industry, brings unmatched expertise in cleanroom, pharmaceutical, semiconductor, data center, commercial, and industrial HVAC systems. As the founder of HVAC Technocrat, he specializes in customized HVAC design, energy efficiency audits, retrofit planning, and turnkey consultancy services across India. His deep understanding of critical environments and complex building needs ensures every solution is efficient, reliable, and future-ready. Through his writings, he simplifies HVAC concepts and shares real-world insights to support professionals, facility managers, and decision-makers.

For any enquiries or project support, feel free to call or WhatsApp at +91 9908091942, email at hvactechnocrats@gmail.com, or visit www.hvactechnocrat.com.