Next pandemic scenarios have shown us the critical importance of maintaining excellent indoor air quality (IAQ) to safeguard health. The COVID-19 pandemic, in particular, underscored how poor IAQ can exacerbate the spread of airborne infections. As we prepare for future health crises, it’s essential to explore advanced solutions that can enhance our indoor environments. Traditional methods, such as basic ventilation and standard air filtration, often fall short when faced with the complexities of global health emergencies.

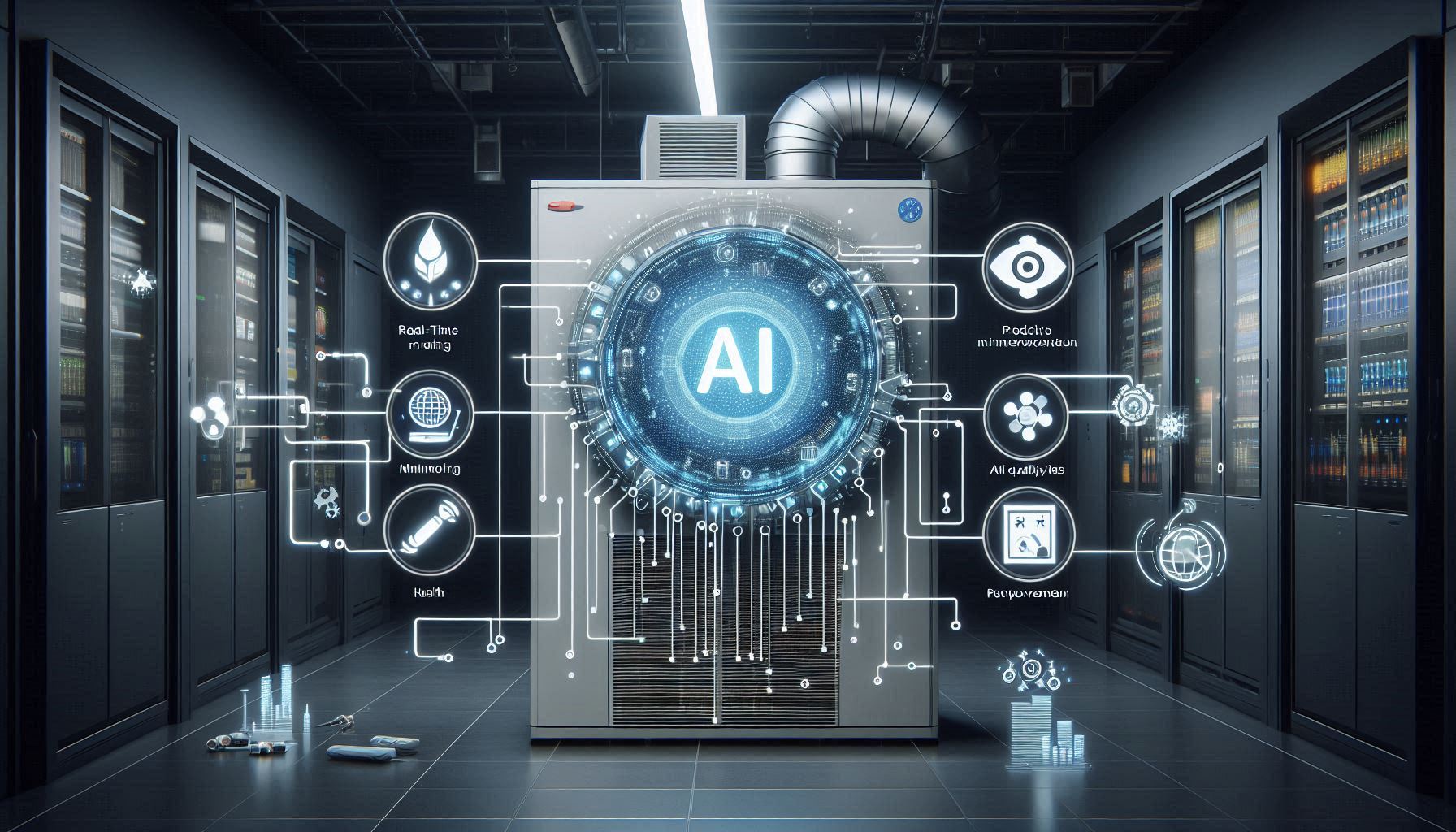

Artificial intelligence (AI) stands out as a promising tool that could transform how we manage IAQ. By integrating AI into HVAC (Heating, Ventilation, and Air Conditioning) systems, we can achieve more precise control and monitoring of indoor air quality. This article delves into how AI can improve HVAC systems, making them more effective in maintaining healthy indoor environments and better preparing us for the next pandemic.

Understanding Indoor Air Quality and Its Importance to beat Next Pandemic

Indoor air quality refers to the cleanliness and healthiness of the air inside buildings. Good IAQ is essential because poor air quality can lead to various health problems, including respiratory issues and the spread of infections. During the pandemic, many buildings were found lacking in effective ventilation, which contributed to the spread of airborne diseases. This has led to a greater focus on improving IAQ through various methods.

Traditionally, buildings relied on basic ventilation and filtration systems. However, these methods often fall short. Air filters are great at capturing particulate matter like dust and pollen, but they do little for gases or viruses. UVGI (Ultraviolet Germicidal Irradiation) systems can kill pathogens, but they have their own drawbacks, such as the potential to produce harmful byproducts. This highlights the need for more advanced solutions, such as AI-enhanced HVAC systems.

To know more about Desiccant Wheels in HVAC How They Improve Indoor Air Quality Click Here

The Role of AI in Enhancing HVAC Systems defeat Next Pandemic

AI has the potential to transform HVAC systems in several ways, making them more effective at maintaining indoor air quality. Here’s how:

- Predictive Maintenance: AI can analyze data from HVAC systems to predict when maintenance is needed. This helps prevent system failures and ensures that the system is always operating efficiently.

- Real-Time Monitoring: AI-powered sensors can provide continuous data on indoor air quality. This allows for immediate adjustments to ventilation and filtration systems, keeping air quality at optimal levels.

- Adaptive Control: AI can adjust HVAC operations in real-time based on current air quality data. For example, if CO2 levels rise, AI can increase ventilation to bring them back down.

- Energy Efficiency: AI can optimize HVAC operations to balance air quality with energy consumption. This ensures that buildings are not only healthier but also more energy-efficient.

- Integration with Other Systems: AI can integrate HVAC systems with lighting and security systems for a comprehensive approach to building management.

How AI Can Address Specific IAQ Challenges for Next Pandemic

AI can tackle several specific challenges related to indoor air quality:

- Managing CO2 Levels: High CO2 levels can indicate poor ventilation. AI can monitor CO2 levels and adjust ventilation accordingly to maintain a healthy environment.

- Handling Pollutants: AI can help manage and filter out various pollutants, including volatile organic compounds (VOCs) and other harmful gases, by using advanced filtration systems.

- Optimizing UVGI Systems: AI can enhance the effectiveness of UVGI systems by ensuring they are used efficiently and reducing the risk of producing harmful byproducts.

The Need for Robust IAQ Regulations and Standards to face Next Pandemic

While AI can greatly improve IAQ, it’s also important to have strong regulations and standards. The pandemic highlighted the need for comprehensive IAQ guidelines to ensure that all buildings maintain high air quality standards. Regulations should require real-time monitoring and response systems to keep air quality in check.

Regulations should also encourage the integration of AI into HVAC systems. By setting standards for AI-powered IAQ management, we can ensure that all buildings are equipped to handle future health crises effectively.

Future Innovations in AI and HVAC Systems

As technology continues to advance, we can expect even more innovations in AI and HVAC systems. Future developments may include:

- More Advanced Sensors: New sensors will provide even more detailed data on indoor air quality, allowing for more precise adjustments.

- Enhanced Machine Learning: AI algorithms will become better at predicting and responding to changes in air quality, improving the overall effectiveness of HVAC systems.

- Integration with Smart Buildings: AI will increasingly be integrated with other smart building technologies, creating more cohesive and responsive building management systems.

To know more about Why Indoor Air Quality Matters in Commercial Spaces Click Here

FAQs

How does AI improve indoor air quality?

AI enhances indoor air quality by providing real-time monitoring, predictive maintenance, and adaptive control of HVAC systems. It can adjust ventilation and filtration based on current air quality data, ensuring a healthier environment.

What are the benefits of using AI in HVAC systems?

AI offers several benefits for HVAC systems, including improved energy efficiency, enhanced air quality management, predictive maintenance, and integration with other building systems. These benefits help create a healthier and more efficient indoor environment.

To know more about How Does AI Optimize Energy Efficiency in Data Center Chiller Plant Click Here

Can AI in HVAC systems help during a next pandemic?

Yes, AI can help during a pandemic by providing real-time data on indoor air quality, adjusting ventilation and filtration systems as needed, and maintaining optimal conditions to reduce the spread of airborne diseases.

What challenges does AI face in HVAC systems?

AI in HVAC systems faces challenges such as high initial costs, the need for regular updates and maintenance, and integration with existing systems. Overcoming these challenges is essential to fully leverage the benefits of AI technology.

How can regulations support AI in HVAC systems?

Regulations can support AI in HVAC systems by setting standards for real-time monitoring, requiring integration of AI technologies, and ensuring that buildings maintain high air quality standards. This helps create a safer and healthier indoor environment.

Conclusion

Preparing for future pandemics requires more than just reacting to crises; it involves proactive measures to improve indoor environments. AI in HVAC systems offers a promising solution for enhancing indoor air quality and ensuring that buildings are ready for health challenges. By leveraging AI technology, we can make significant strides in maintaining healthier indoor environments and better prepare for future pandemics. The lessons learned from the COVID-19 pandemic should drive us to embrace these innovations and make our buildings safer and more resilient.

To know more about Innovations and Trends in HVAC Industry Click Here

About The Author

Omprakash Ramagiri; as the Founder of HVAC Technocrats, I bring over 18 years of experience as a Mechanical Engineer specializing in HVAC (Central Air-conditioning) for Commercial, Cleanrooms, Data centers, and Petrochemical industries. Throughout my career, I’ve held pivotal roles at companies like TATA Consulting Engineers, MW Zander (for Cleanroom solutions), Bluestar Malaysia, and ETA in Dubai. I’ve managed international HVAC projects and gained valuable exposure in dynamic markets like Dubai and Saudi Arabia. With a passion for excellence and a commitment to innovative solutions, I specialize in designing Class 10K & 100K Cleanrooms for various industries. Connect with me to explore collaborations in HVAC design, project sales, and consultancy. Click to visit the Author’s Linkedin page

Disclaimer: The content and images are for educational purposes and knowledge enhancement only. They may not depict actual products or situations. Outcomes may vary. Content is generated by AI and reviewed by industry experts, including Author.