Becoming a successful HVAC Design Engineer requires a unique combination of technical expertise, creativity, and adaptability. From designing efficient climate control systems for residential spaces to ensuring precise environmental conditions in critical environments like cleanrooms and data centers, HVAC design engineers play a pivotal role in shaping modern infrastructure. This article explores the essential steps, emerging trends, and real-world insights that can help you thrive as an HVAC Design Engineer, whether you’re just starting your career or looking to refine your skills.

Understanding the Role of an HVAC Design Engineer

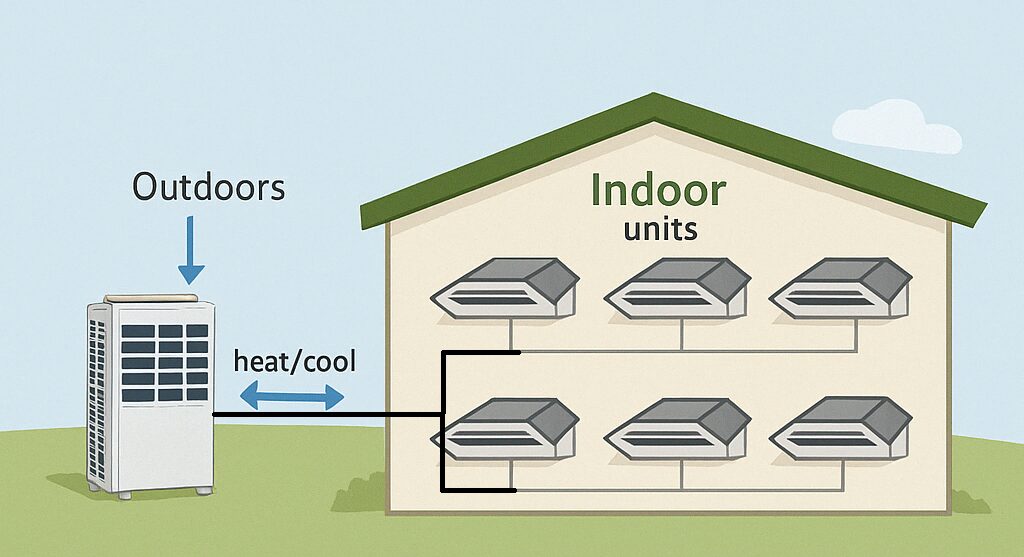

An HVAC Design Engineer is responsible for creating detailed plans and specifications for heating, ventilation, and air conditioning systems that regulate temperature, humidity, and air quality in various settings. These professionals collaborate closely with architects, contractors, and facility managers to ensure systems are not only functional but also energy-efficient and sustainable. For instance, designing HVAC systems for pharmaceutical cleanrooms demands precise temperature and humidity control, while systems for data centers focus on cooling efficiency and redundancy.

A strong foundation in psychrometry (the study of air properties) and heat load calculations is crucial for success. Learn more about these concepts in our detailed guide on heat load calculation.

The Educational Pathway to Becoming an HVAC Design Engineer

The journey to becoming a successful HVAC Design Engineer begins with formal education and hands-on experience. Here’s how you can build a strong foundation:

Pursue Relevant Degrees

Most employers prefer candidates with a bachelor’s degree in mechanical engineering, HVAC technology, or a related field. Courses in thermodynamics, fluid mechanics, and refrigeration systems provide a solid grounding in the principles of HVAC design.

Gain Practical Experience

Internships and apprenticeships are invaluable for gaining hands-on skills. For example, working alongside seasoned professionals on projects like geothermal HVAC systems installation can deepen your understanding of sustainable technologies. Explore tips on selecting eco-friendly systems in our blog on geothermal HVAC systems.

Obtain Certifications

Certifications from recognized bodies such as ASHRAE or ISHRAE enhance credibility. Specialized certifications in areas like BIM (Building Information Modeling) or energy auditing can further set you apart in the competitive job market.

Skills Every HVAC Design Engineer Should Master

Success as an HVAC Design Engineer hinges on mastering a mix of technical and soft skills:

Technical Proficiency

CFD Analysis: Computer-based airflow simulations help predict system performance before implementation.

Energy Efficiency Audits: Conducting audits ensures systems operate optimally while reducing energy costs. Discover more about audits in our article on energy efficiency audits.

Problem-Solving Abilities

An HVAC design engineer must troubleshoot issues effectively. For instance, identifying the root cause of inconsistent airflow in a building could involve checking ductwork design or recalibrating dampers.

Communication Skills

Clear communication with clients and team members is crucial. Explaining complex HVAC concepts in simple terms builds trust and fosters collaboration.

Emerging Trends Shaping the HVAC Design Industry

Staying updated with the latest trends is vital for any aspiring HVAC Design Engineer:

AI-Driven Optimization

Artificial intelligence is revolutionizing HVAC systems by enabling predictive maintenance and real-time performance monitoring. Smart HVAC systems like these use machine learning algorithms to optimize energy consumption.

Sustainable Solutions

With growing emphasis on green buildings, HVAC design engineers are increasingly incorporating renewable energy sources. Solar-powered air conditioners are gaining traction, especially in regions like India. Learn more in our solar AC buying guide.

Advanced Filtration Systems

Indoor air quality has become a priority post-pandemic. Technologies like HEPA filters and UV-C disinfection are now standard in many HVAC designs.

Challenges Faced by HVAC Design Engineers

While rewarding, the path to success as an HVAC Design Engineer comes with its share of challenges:

Adapting to Climate Change

Rising global temperatures necessitate rethinking traditional cooling methods. Engineers must design systems capable of handling extreme heat waves without excessive energy usage.

Navigating Complex Codes

Compliance with local and international codes, such as ECBC (Energy Conservation Building Code), requires meticulous attention to detail.

Balancing Cost and Efficiency

Clients often demand cost-effective yet high-performing systems. Achieving this balance calls for innovative thinking and thorough planning.

Real-World Case Studies

Case studies offer valuable lessons for budding HVAC Design Engineers:

Data Center Cooling: A Mumbai-based data center reduced energy consumption by 25% after implementing AI-driven chiller plants. Read more about this trend in our article on AI-powered chiller plants.

Cleanroom Design: A pharmaceutical facility in Hyderabad achieved ISO Class 5 certification thanks to precise HVAC design. Dive deeper into cleanroom standards here.

Expert Insights: Lessons from 18 Years in the Field

With over 18 years of hands-on experience in the HVAC industry, it’s clear that success as an HVAC design engineer requires meticulous groundwork and a proactive approach. Even after nearly two decades, preparing CAD drawings, conducting detailed heat load calculations, and sizing ducts and pipes using precise charts remain essential practices. These foundational steps ensure accuracy and efficiency in system design.

Additionally, tasks like static pressure calculations, sectional drawing preparations, and site visits are non-negotiable for achieving perfection. For instance, checking ceiling height availability during site visits can prevent costly redesigns later, while proactive visualization helps anticipate challenges before they arise. Thoughtful planning extends to plant room layouts, where optimizing space and accessibility is critical for seamless operations. By embracing these practices, HVAC design engineers not only deliver high-quality results but also build trust with clients and stakeholders.

Job Opportunities in HVAC Industry

If you’re an aspiring professional looking to build a rewarding career in the HVAC industry, we’re here to help! Whether you’re a fresh graduate or an experienced, there are countless opportunities in areas like HVAC design, planning, installation, maintenance, and consultancy. To assist you in finding the right role within my network, please send me your updated CV at hvactechnocrats@gmail.com for my records. This will enable me to recommend you for suitable openings in my circle and support your career growth in the dynamic HVAC field. Reach out today to take the next step toward success!

Tips for Career Growth as an HVAC Design Engineer

Continuous learning and networking are key to advancing your career:

Attend industry conferences and workshops to stay updated on innovations.

Join professional organizations like ISHRAE or ASHRAE to connect with peers.

Leverage online platforms like LinkedIn to showcase your expertise and engage with thought leaders.

FAQs

What qualifications do I need to become an HVAC design engineer?

A bachelor’s degree in mechanical engineering or HVAC technology is typically required, along with relevant certifications.

How long does it take to become an HVAC design engineer?

It usually takes four years to complete a bachelor’s degree, followed by additional time for certifications and hands-on experience.

Is programming knowledge necessary for HVAC design engineers?

While not mandatory, familiarity with programming languages like Python can be beneficial for working with AI-driven systems.

Can HVAC design engineers work internationally?

Yes, HVAC design engineers can find opportunities worldwide, provided they meet regional licensing requirements.

What industries hire HVAC design engineers?

HVAC design engineers are employed in sectors like construction, healthcare, manufacturing, and IT infrastructure.

How important is sustainability in HVAC design engineering?

Sustainability is critical, as energy-efficient systems reduce operational costs and environmental impact.

Disclaimer

Some links in this article are affiliate links, such as those for Amazon products. These may generate a small commission at no extra cost to you, supporting our work. We never compromise editorial integrity for partnerships.

About the Author

Mr. Om Prakash, with over 18 years of hands-on experience in the HVAC industry, brings unmatched expertise in cleanroom, pharmaceutical, semiconductor, data center, commercial, and industrial HVAC systems. As the founder of HVAC Technocrat, he specializes in customized HVAC design, energy efficiency audits, retrofit planning, and turnkey consultancy services across India. His deep understanding of critical environments and complex building needs ensures every solution is efficient, reliable, and future-ready. Through his writings, he simplifies HVAC concepts and shares real-world insights to support professionals, facility managers, and decision-makers. For any enquiries or project support, feel free to call or WhatsApp at +91 9908091942, email at hvactechnocrats@gmail.com, or visit www.hvactechnocrat.com.