Choosing the right HVAC valves is vital for your heating and cooling system’s efficiency and longevity. With numerous valve types available, each with specific functions, it’s essential to understand their roles to make informed decisions. This guide will help you navigate the selection process, ensuring your HVAC system operates optimally.

What Factors Should You Consider When Selecting HVAC Valves?

When selecting HVAC valves, several critical factors come into play. First, consider the system’s specific needs. For instance, do you need precise flow control, pressure regulation, or temperature management? Next, think about the operating environment. Extreme temperatures and exposure to corrosive substances can affect valve performance. Compatibility with HVAC system components is also crucial to ensure durability and reliability. Additionally, evaluate the ease of maintenance and accessibility for servicing. By considering these factors, you can select valves that meet your system’s requirements and enhance overall performance.

How Do Different HVAC Valve Types Impact System Efficiency?

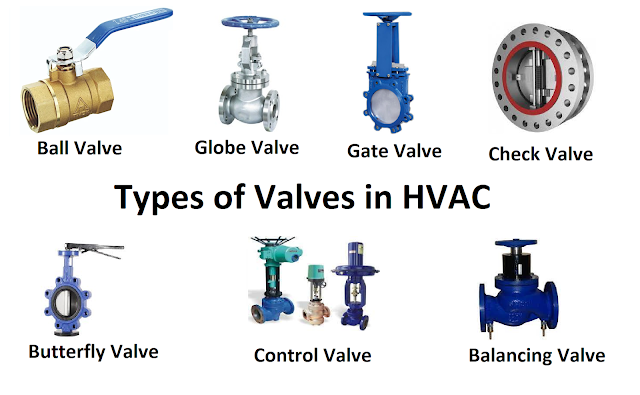

Different HVAC valve types can significantly impact system efficiency. Here are some common types and their roles:

- 2-Way Control Valves: Regulate the flow rate by opening and closing in response to control signals, ensuring precise temperature control.

- 3-Way Control Valves: Allow for mixing or diverting flow, which is useful in systems requiring balanced temperature distribution.

- Balancing Valves: Maintain even pressure and flow rates throughout the system, reducing energy consumption and enhancing efficiency.

Each valve type has unique characteristics that can optimize or hinder system performance, so understanding their roles is crucial.

To know more about How BTU Meters Enhance Energy Efficiency in HVAC Systems Click Here

To know more about Net Zero Energy Building HVAC Systems Click Here

What Are the Main Functions of Various HVAC Valves?

HVAC valves serve several primary functions, including flow regulation, pressure control, and system protection. Here are some common HVAC valves and their functions:

- Ball Valves: Known for their simple on/off control and durability.

- Butterfly Valves: Provide quick shutoff capabilities with minimal pressure drop.

- Check Valves: Prevent backflow, ensuring system safety and efficiency.

- Globe Valves: Offer precise flow control, making them ideal for throttling applications.

- Motorized On/Off Valves: Automate control, enhancing system responsiveness and reducing manual intervention.

- Valve Actuators: Automate the opening and closing of valves, improving efficiency and control.

Understanding these functions helps in selecting the right valves for specific needs.

How to Choose the Right HVAC Valve for Your System Requirements?

Choosing the right HVAC valve involves understanding your system’s specific requirements. Assess the desired control function, such as modulating or on/off control. Evaluate the system’s pressure and temperature ranges to ensure the valve can withstand these conditions. Consider the valve’s flow characteristics, such as linear or equal percentage, to match the system’s performance needs. Also, account for the installation space and the need for automation when choosing between manual and motorized valves. By carefully considering these factors, you can select the most appropriate valve for your HVAC system.

To know more about How to Choose The Right HVAC Valve for Commercial Building Click Here

What Are the Key Differences Between Motorized and Manual HVAC Valves?

The primary difference between motorized and manual HVAC valves lies in their operation and control mechanisms. Manual valves require physical intervention to open or close, making them suitable for applications where infrequent adjustments are needed. Motorized valves, on the other hand, are controlled by actuators that respond to control signals from the HVAC system. This automation allows for precise and timely adjustments, improving system efficiency and reducing the need for manual oversight. Motorized valves are ideal for modern, automated HVAC systems.

How Do Material Choices Affect HVAC Valve Performance and Longevity?

Material selection is critical in determining the performance and longevity of HVAC valves. Common materials include brass, stainless steel, and PVC. Brass valves are durable and resistant to corrosion, making them suitable for various applications. Stainless steel valves offer higher corrosion resistance and strength, ideal for harsh environments. PVC valves are lightweight and resistant to chemicals, often used in less demanding applications. The right material choice ensures the valve can withstand operational stresses and environmental conditions, reducing maintenance and replacement costs.

What Are the Benefits of Using Smart HVAC Valves in Modern Systems?

Smart HVAC valves integrate advanced sensors and control technologies to enhance system performance and efficiency. These valves can automatically adjust to changing conditions, optimizing flow rates and reducing energy consumption. They provide real-time data on system performance, enabling predictive maintenance and reducing downtime. Smart valves can be integrated into building automation systems, allowing for centralized control and monitoring. This connectivity ensures optimal system operation and contributes to energy savings and improved indoor air quality.

How Can You Ensure Proper Sizing of HVAC Valves for Optimal Performance?

Proper sizing of HVAC valves is essential to ensure optimal system performance. Undersized valves can cause excessive pressure drops and restrict flow, while oversized valves may lead to poor control and increased wear. To ensure correct sizing, calculate the required flow rate and pressure drop for the specific application. Use manufacturers’ sizing charts and software tools to select the appropriate valve size. Proper sizing ensures efficient operation, reduces energy consumption, and extends the lifespan of the valves and associated equipment.

What Are the Latest Innovations in HVAC Valve Technology?

Recent innovations in HVAC valve technology focus on enhancing efficiency, control, and connectivity. Pressure-Independent Balancing and Control Valves (PIBCV) combine balancing and control functions, simplifying installation and improving performance. Smart valves with integrated IoT capabilities provide real-time monitoring and remote control, optimizing system operation. Advanced materials and coatings improve durability and corrosion resistance, extending valve life. Innovations in actuator design enhance responsiveness and precision, contributing to better overall system performance.

To know more about The Latest Innovations in HVAC Valve Technology Click Here

How Do HVAC Control Valves Enhance Building Automation and Efficiency?

HVAC control valves play a pivotal role in building automation and efficiency. By regulating flow rates and maintaining desired temperatures, they ensure optimal comfort levels and energy usage. Motorized control valves can be integrated into building management systems (BMS), allowing for automated adjustments based on real-time data. This integration enables efficient energy management, reduces operational costs, and enhances occupant comfort. Advanced control algorithms and sensors further improve the responsiveness and accuracy of HVAC systems.

What Role Do Pressure-Independent Control Valves Play in HVAC Systems?

Pressure-Independent Control Valves (PICVs) are essential for maintaining consistent flow rates regardless of pressure fluctuations in the system. PICVs combine the functions of a balancing valve and a control valve, simplifying system design and installation. They ensure optimal performance by maintaining the set flow rate, reducing energy consumption, and improving system stability. PICVs are particularly beneficial in variable flow systems, where pressure changes can impact performance. Their ability to maintain precise control enhances system efficiency and comfort.

How to Troubleshoot and Maintain Different Types of HVAC Valves?

Regular maintenance and troubleshooting of HVAC valves are crucial to ensure system reliability and performance. Inspect valves for signs of wear, corrosion, or leakage, and replace damaged components promptly. Clean valve internals to prevent clogging and ensure smooth operation. For motorized valves, check actuator performance and calibration. Troubleshoot common issues such as improper flow rates or pressure drops by verifying valve sizing and installation. Implementing a proactive maintenance schedule helps prevent unexpected failures and extends the lifespan of HVAC valves.

To know more about HVAC Valves How to Troubleshoot Common Issues Click Here

What Are the Cost-Effective Solutions for HVAC Valve Selection?

Cost-effective HVAC valve selection involves balancing initial investment with long-term operational savings. Ball valves and butterfly valves offer cost-effective solutions for on/off control with minimal pressure drop. Check valves ensure system protection at a reasonable cost. For precise flow control, globe valves and PIBCVs provide efficient performance with lower energy consumption. Consider the total cost of ownership, including maintenance and energy savings, when selecting valves. Investing in high-quality valves can reduce long-term costs and improve system reliability.

How Do Regulatory Standards Influence HVAC Valve Selection?

Regulatory standards play a significant role in HVAC valve selection, ensuring safety, performance, and environmental compliance. Standards such as ASHRAE and IGBC provide guidelines for valve performance, installation, and maintenance. Compliance with these standards ensures that valves meet industry benchmarks for efficiency and reliability. Additionally, adhering to regulatory standards can enhance system certification and marketability, particularly in green building projects. Understanding and incorporating relevant standards into valve selection helps achieve compliance and optimize system performance.

Conclusion

Selecting the right HVAC valves is essential for the efficient and reliable operation of heating, ventilation, and air conditioning systems. By understanding the functions, impacts, and innovations of various valve types, HVAC professionals can make informed decisions that enhance system performance and longevity. Proper sizing, material selection, and adherence to regulatory standards further ensure optimal valve performance. With advancements in smart valve technology and building automation, HVAC systems can achieve greater efficiency, comfort, and sustainability.

About The Author

Omprakash Ramagiri; as the Founder of HVAC Technocrats, I bring over 18 years of experience as a Mechanical Engineer specializing in HVAC (Central Air-conditioning) for commercial, cleanrooms, data centers, and Petrochemical industries. Throughout my career, I’ve held pivotal roles at companies like TATA Consulting Engineers, MW Zander (for Cleanroom solutions), Bluestar Malaysia, and ETA in Dubai. I’ve managed international HVAC projects and gained valuable exposure in dynamic markets like Dubai and Saudi Arabia. With a passion for excellence and a commitment to innovative solutions, I specialize in designing Class 10K & 100K Cleanrooms for various industries. Connect with me to explore collaborations in HVAC design, project sales, and consultancy. Click to visit the Author’s Linkedin page

Disclaimer: The content and images are for educational purposes and knowledge enhancement only. They may not depict actual products or situations. Outcomes may vary. Content is generated by AI and reviewed by industry experts, including Author.

Leave a Reply