In today’s competitive industrial and commercial landscape, optimizing HVAC systems isn’t just about comfort—it’s about cost savings, energy efficiency, and sustainability. Whether you manage a pharmaceutical cleanroom, a semiconductor facility, a data center, or a large commercial building, an experienced HVAC consultant can help you cut operational costs, enhance performance, and meet regulatory standards.

This article explores how an HVAC consultant add value, the key services they offer, and real-world examples of energy and cost savings that can transform your HVAC systems for maximum efficiency and sustainability.

Why Hire an HVAC Consultant?

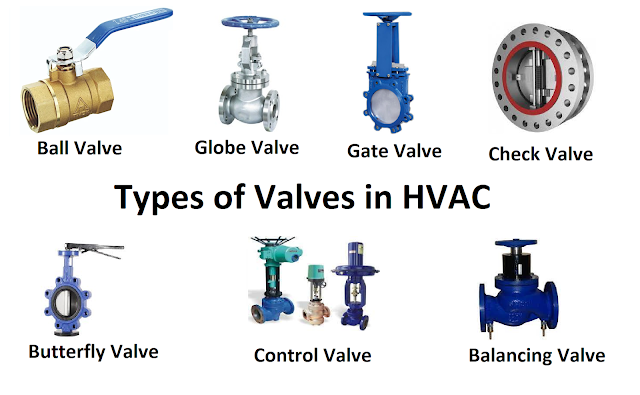

HVAC systems account for 40-60% of a building’s energy consumption. However, poor design can lead to skyrocketing bills, while frequent breakdowns drive up maintenance costs. Additionally, non-compliance with energy codes may result in penalties. Moreover, Poor indoor air quality (IAQ) affecting health & productivity. For these reasons, professional intervention is critical.

An HVAC consultant identifies inefficiencies, recommends upgrades, and ensures systems run at peak performance with minimal waste.

Key Services Offered by an HVAC Consultant

1. Value Engineering: Optimizing Costs Without Compromising Quality

Instead of overspending on oversized equipment or unnecessary features, consultants perform value engineering—analyzing system requirements and suggesting cost-effective alternatives.

✅ Case Study: A Hyderabad-based IT park reduced HVAC installation costs by ₹58 lakhs after a consultant optimized chiller capacity, piping sizing and ductwork routing layout.

2. Energy Audits: Pinpointing Waste & Recommending Solutions

Energy audits assess how efficiently your HVAC system operates and identify:

- Overcooling/overheating zones

- Air leaks in ducts

- Inefficient equipment (old chillers, pumps, fans)

- Opportunities for heat recovery

✅ For Instance: A pharmaceutical plant in Bengaluru cut energy bills by 25% after an audit revealed excessive fan power usage—solved by switching to EC motors.

3. Retrofit Design Analysis: Upgrading Old Systems for Better Efficiency

Many facilities run on decades-old HVAC systems that guzzle energy. Consultants analyze:

- Replacement vs. repair economics

- New tech options (VRF, inverter chillers, smart controls)

- ROI on energy-efficient retrofits

✅ In another Example: A commercial complex in Mumbai replaced its 20-year-old chillers with magnetic-bearing models, reducing energy consumption by 40%—payback in 33 months.

4. Greenfield Projects: Designing Efficient HVAC from Scratch

For new constructions (data centers, cleanrooms, industrial plants), consultants ensure:

- Right-sizing equipment (avoiding over/under-capacity)

- Sustainable design (solar-assisted cooling, efficient motors options)

- Compliance with ASHRAE, ISHRAE, ECBC, and LEED standards

✅ Similarly: A semiconductor facility in Chennai saved ₹1.2 crore/year by integrating adiabatic cooling instead of traditional DX systems.

5. Planning, Estimation & Tendering: Avoiding Costly Mistakes

A poorly planned HVAC project can lead to budget overruns and delays. Consultants help with:

- Accurate load calculations

- Equipment selection (chillers, AHUs, pumps)

- Bid evaluation & contractor selection

✅ Another Case Study: A hospital in Bangalore avoided ₹25 lakhs in rework after a consultant corrected incorrect duct sizing in initial plans.

HVAC Sustainability & Energy Efficiency Solutions

With rising electricity costs and stricter environmental regulations, businesses must adopt sustainable HVAC practices. Consultants recommend:

- Heat recovery systems (waste heat reuse)

- Mag-Lev bearing chillers

- Solar-powered motors for AHUs and Fans

- AI-driven predictive maintenance

- Thermal energy storage

- Building automation systems (BAS) for smart controls

✅ Case Study: A Hyderabad mall installed IoT-based HVAC controls, reducing energy use by 25% while maintaining optimal comfort.

Why Choose Mr. Om Prakash – HVAC Consultant at www.hvactechnocrat.com?

With 18+ years of expertise, Mr. Om Prakash has helped pharmaceutical plants, data centers, semiconductor facilities, and commercial buildings across India and abroad optimize their HVAC systems for energy efficiency and cost savings.

What Sets Him Apart?

✔ Deep Technical Knowledge – Specializes in cleanrooms, data centers, industrial HVAC, and green building compliance.

✔ Hands-On Experience – Successfully executed 100+ projects in design, audits, retrofits, and energy optimization.

✔ Cost-Saving Strategies – Expertise in value engineering to reduce capital and operational expenses.

✔ Sustainability Focus – Designs systems aligned with ECBC, LEED, ISHRAE and ASHRAE standards for long-term efficiency.

Services Offered:

🔹 HVAC Design & Planning for commercial buildings

🔹 Energy Efficiency Audits

🔹 Retrofit & Modernization Studies

🔹 Cleanroom, Pharma and Semiconductor HVAC Solutions

🔹 Data Center Cooling Optimization

🔹 Tender Documentation & Bid Evaluation

Real-World Impact:

🏭 A Hyderabad pharma company saved ₹42 lakhs/year after Mr. Om Prakash redesigned their HVAC system’s capacity, airflow & filtration system.

🏢 A commercial tower reduced HVAC energy use by 30% through AI-based load optimization.

📞 For Expert HVAC Consulting in Hyderabad & Across India:

📱 Call/WhatsApp: +91 9908091942

📧 Email: hvactechnocrats@gmail.com

🌐 Visit: www.hvactechnocrat.com

FAQs

1. How much can an HVAC consultant save me?

Savings depend on system inefficiencies—typically 20-40% on energy bills and 10-30% on maintenance costs.

2. Is hiring a HVAC consultant worth it for small businesses?

Yes! Even small facilities can save lakhs annually with proper HVAC optimization.

3. How long does an energy audit take?

Usually 2-5 days, depending on facility size.

4. Can HVAC consultant help with green building certifications?

Absolutely! They ensure compliance with LEED, IGBC, and ECBC norms.

5. What’s the ROI on HVAC retrofits?

Most projects pay back in 2-4 years through energy savings.

6. Do HVAC consultant handle contractor coordination?

Yes, they oversee design, installation, and commissioning to avoid errors.

Final Thoughts

An HVAC consultant isn’t an expense—it’s an investment that pays off in lower bills, fewer breakdowns, and better compliance. Whether you need energy audits, retrofit designs, or greenfield project planning, Mr. Om Prakash at www.hvactechnocrat.com brings 18+ years of expertise to deliver cost-effective, sustainable HVAC solutions.

📞 Contact today for a consultation!

📱 +91 9908091942 | 📧 hvactechnocrats@gmail.com

Disclosure: Some links may be affiliate-based, supporting our research at no extra cost to you. We maintain strict editorial independence.