The pharmaceutical industry is evolving rapidly, and pharma cleanrooms are at the forefront of this transformation. As we approach 2025, advancements in technology are reshaping how cleanrooms are designed, operated, and maintained to ensure compliance with stringent standards like ISO Class 5, ASHRAE, and ISHRAE. These innovations not only enhance efficiency but also improve product quality and safety. In this article, we’ll explore the top trends in pharma cleanroom technology for 2025, offering insights into how these advancements can benefit your operations.

Understanding the Role of Pharma Cleanroom

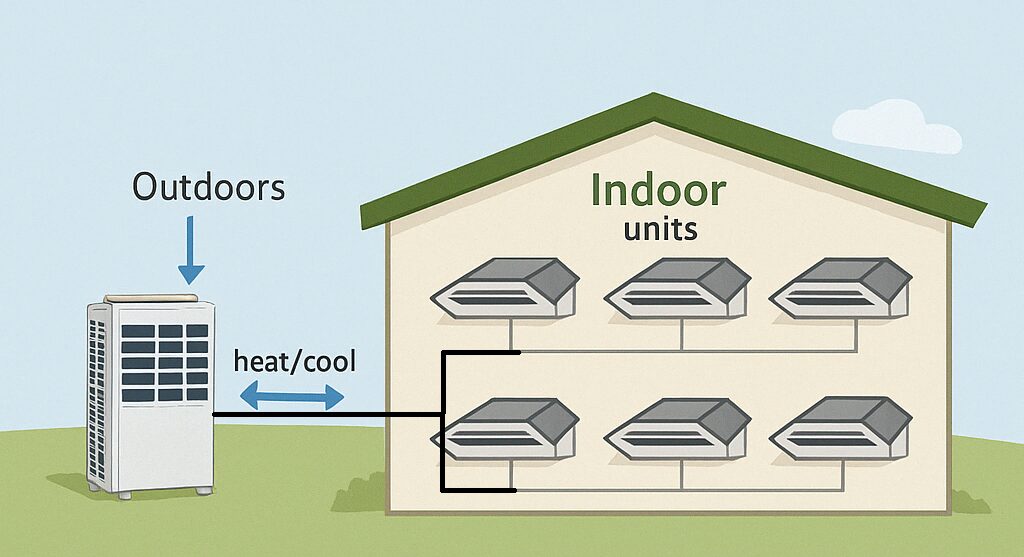

A pharmaceutical cleanroom is a carefully controlled space designed to limit contaminants such as dust, airborne microbes, and aerosol particles. This environment is crucial for producing safe, high-quality medications that meet strict industry standards. These environments are critical for processes such as drug formulation, packaging, and sterile manufacturing. For instance, maintaining precise temperature and humidity levels in a cleanroom ensures the stability of sensitive compounds, while advanced filtration systems prevent contamination.

Learn more about cleanroom classifications and their importance in our detailed guide on cleanroom technology.

Emerging Technologies in Pharma Cleanroom

As we look toward 2025, several technological trends are set to revolutionize pharma cleanrooms:

AI-Driven Monitoring Systems

Artificial intelligence (AI) is transforming cleanroom operations by enabling real-time monitoring and predictive maintenance. AI-powered sensors can detect anomalies in air quality, temperature, and humidity, alerting operators before issues escalate. For example, a pharmaceutical facility in Hyderabad reduced contamination risks by 40% after implementing AI-driven monitoring systems. Explore how AI optimizes HVAC systems in data centers here.

Automation and Robotics

Automation is becoming increasingly prevalent in pharma cleanrooms, with robotic systems handling repetitive tasks like material handling and equipment sterilization. This minimizes human intervention, reducing the risk of contamination. For instance, a leading biotech company in Pune integrated robotic arms for packaging, achieving a 25% increase in operational efficiency.

Advanced Filtration Systems

HEPA and ULPA filters remain staples in cleanroom design, but innovations such as electrostatic filtration and UV-C disinfection are gaining traction. These technologies ensure superior air quality by trapping submicron particles and neutralizing pathogens. Discover more about indoor air quality solutions here.

Sustainable Cleanroom Design

Sustainability is a growing priority in cleanroom design. Energy-efficient HVAC systems, renewable energy sources, and eco-friendly materials are being incorporated to reduce carbon footprints. For example, a pharma plant in Bengaluru achieved LEED certification by integrating solar-powered HVAC units. Learn more about sustainable HVAC systems here.

Challenges in Pharma Cleanroom Technology

While modern technologies bring impressive advantages, they also come with their own set of challenges:

High Initial Costs

Implementing cutting-edge technologies like AI and robotics requires substantial investment. However, the long-term savings in energy efficiency and reduced contamination risks often justify the expense.

Regulatory Compliance

Meeting national and international standards such as ISO Class 5, BIS, and ECBC is non-negotiable. Regular audits and certifications ensure adherence to these guidelines.

Skilled Workforce Shortage

Operating advanced cleanroom technologies demands specialized skills. Training programs and workshops are essential to equip workers with the necessary expertise.

Case Studies: Real-World Applications

To better understand the impact of these trends, let’s look at some real-world examples:

Data-Driven Cleanroom Optimization

For example, a pharmaceutical company in Mumbai adopted IoT-enabled sensors to track air quality and monitor pressure differences in real time, ensuring tighter control over cleanroom conditions. This proactive approach reduced contamination incidents by 35%, ensuring consistent product quality.

Green Cleanroom Initiatives

A Chennai-based facility adopted geothermal HVAC systems to achieve energy savings of up to 30%. By leveraging renewable energy, they not only reduced operational costs but also contributed to environmental sustainability. Explore geothermal HVAC options here.

Future Trends in Pharma Cleanroom

Looking ahead, several trends are expected to shape the future of pharma cleanrooms:

Integration of Blockchain Technology

Blockchain can enhance traceability and transparency in pharmaceutical manufacturing. By recording every step of the production process, it ensures compliance and reduces the risk of counterfeit drugs entering the supply chain.

Augmented Reality (AR) for Training

AR is being used to train cleanroom operators in a virtual environment, allowing them to practice procedures without risking contamination. This immersive approach improves learning outcomes and reduces training time.

Smart Materials in Construction

Innovative materials like antimicrobial coatings and self-healing surfaces are being used in cleanroom construction to minimize contamination risks and extend the lifespan of equipment.

Tips for Implementing Advanced Technologies in Pharma Cleanroom

To stay competitive in 2025, here are a few smart moves:

Adopt AI and IoT technologies to boost real-time system monitoring and support predictive maintenance for smoother operations. Look into renewable energy options, like solar-powered HVAC systems, to help lower operating costs and support sustainability goals. Prioritize staff training to ensure smooth adoption of new technologies.

FAQ: Pharma Cleanroom

What is a pharma cleanroom?

A pharma cleanroom is a controlled environment designed to minimize contaminants during pharmaceutical production, ensuring product safety and quality.

Why is temperature control important in a pharma cleanroom?

Temperature control is critical to maintaining the stability of sensitive compounds and preventing degradation during manufacturing.

How do HEPA filters work in cleanrooms?

HEPA filters trap particles as small as 0.3 microns, ensuring superior air quality in cleanroom environments.

What are the latest trends in pharma cleanroom technology?

Emerging trends include AI-driven monitoring, automation, advanced filtration systems, and sustainable design practices.

How can I ensure regulatory compliance in my cleanroom?

Regular audits, staff training, and adherence to standards like ISO Class 5 and ECBC are essential for maintaining compliance.

What role does sustainability play in cleanroom design?

Sustainability reduces energy consumption and environmental impact, aligning with global green building initiatives like IGBC and LEED.

Disclaimer

Some links in this article are affiliate links, such as those for Amazon products. These may generate a small commission at no extra cost to you, supporting our work. We never compromise editorial integrity for partnerships.

About the Author

Mr. Om Prakash, with over 18 years of hands-on experience in the HVAC industry, brings unmatched expertise in cleanroom, pharmaceutical, semiconductor, data center, commercial, and industrial HVAC systems. As the founder of HVAC Technocrat, he specializes in customized HVAC design, energy efficiency audits, retrofit planning, and turnkey consultancy services across India. His deep understanding of critical environments and complex building needs ensures every solution is efficient, reliable, and future-ready. Through his writings, he simplifies HVAC concepts and shares real-world insights to support professionals, facility managers, and decision-makers. For any enquiries or project support, feel free to call or WhatsApp at +91 9908091942, email at hvactechnocrats@gmail.com, or visit www.hvactechnocrat.com.