Make-up Air Units MAU Design for Semiconductor Industry represent the backbone of semiconductor cleanroom environmental control systems. These specialized units maintain the precise atmospheric conditions essential for manufacturing integrated circuits and microprocessors. Unlike conventional HVAC systems, semiconductor cleanroom MAU systems must deliver unprecedented levels of air purity, temperature stability, and humidity control to prevent contamination that could destroy millions of dollars worth of semiconductor wafers.

The semiconductor industry operates within tolerances measured in nanometers, where even microscopic particles can render entire production batches unusable. Therefore, MAU design becomes a critical engineering discipline that directly impacts product yield, manufacturing efficiency, and ultimately, the profitability of semiconductor fabrication facilities. Modern fab facilities invest heavily in sophisticated MAU systems because the cost of contamination far exceeds the investment in premium environmental control equipment.

Enjoying this content? Get expert HVAC updates on our Telegram Channel.

Fundamental Design Principles for Semiconductor MAU Systems

Semiconductor MAU design follows stringent engineering principles that prioritize contamination prevention above all other considerations. The primary design objective focuses on delivering ultra-clean air at precise temperature and humidity levels while maintaining positive pressure differentials throughout the cleanroom environment. These systems must operate continuously without interruption, as even brief shutdowns can compromise ongoing manufacturing processes and result in substantial financial losses.

The design process begins with comprehensive contamination risk assessment, identifying potential sources of particles, chemicals, and biological contaminants that could affect semiconductor manufacturing. Engineers must consider both external contamination sources and internal generation mechanisms, including human activity, equipment operations, and material handling processes. This holistic approach ensures that MAU systems address all potential contamination pathways while maintaining optimal environmental conditions.

Furthermore, cleanroom design and construction requirements demand that MAU systems integrate seamlessly with architectural elements, including ceiling systems, wall configurations, and floor layouts. The interdisciplinary nature of semiconductor facility design requires close collaboration between HVAC engineers, architects, process engineers, and contamination control specialists to achieve optimal results.

Advanced Filtration Technologies in MAU Design

Modern semiconductor MAU systems incorporate multiple filtration stages to achieve the ultra-clean air quality required for nanometer-scale manufacturing processes. The filtration hierarchy typically begins with pre-filters that remove larger particles and protect downstream components from premature loading. These initial stages utilize pleated filters with efficiency ratings appropriate for the local environmental conditions and outdoor air quality.

The secondary filtration stage employs high-efficiency particulate air (HEPA) filters that capture particles down to 0.3 microns with 99.97% efficiency. However, semiconductor applications often require even higher performance, leading to the adoption of ultra-low penetration air (ULPA) filters that achieve 99.999% efficiency for particles as small as 0.12 microns. These advanced filters undergo rigorous testing and certification processes to ensure they meet stringent cleanroom standards.

HEPA filter systems represent the cornerstone of semiconductor air purification, requiring careful selection, installation, and maintenance protocols. The filter housing design must minimize bypass leakage while providing adequate access for replacement and testing procedures. Additionally, molecular filtration technologies address gaseous contaminants that could affect semiconductor processing, including airborne molecular contamination (AMC) that traditional particulate filters cannot capture.

Temperature and Humidity Control Strategies

Semiconductor manufacturing processes demand extremely precise temperature and humidity control, often within tolerances of ±0.1°C and ±1% relative humidity. These tight specifications require sophisticated MAU design approaches that incorporate multiple control loops, redundant sensors, and advanced control algorithms. Precise temperature control systems utilize staged heating and cooling components to maintain stability while responding quickly to load variations.

The thermal management strategy must account for both sensible and latent heat loads generated by manufacturing equipment, lighting systems, and personnel. Process equipment can generate substantial heat loads that vary throughout production cycles, requiring MAU systems to respond dynamically while maintaining stable conditions. Advanced control systems utilize predictive algorithms that anticipate load changes and adjust system operation proactively.

Humidity control presents unique challenges in semiconductor environments, where moisture can affect chemical processes and promote unwanted reactions. Semiconductor humidity control systems typically employ desiccant dehumidification technologies that provide precise moisture removal without introducing contaminants. These systems must operate continuously and maintain consistent performance across varying outdoor conditions and internal loads.

Pressure Differential Management and Zoning

Maintaining proper pressure differentials represents a fundamental aspect of semiconductor cleanroom design, preventing contamination migration between different cleanliness zones. Cleanroom pressure differential optimization requires careful analysis of airflow patterns, door operations, and equipment exhaust requirements. The MAU system must provide sufficient supply air to maintain positive pressures while accommodating exhaust requirements from process equipment.

The zoning strategy typically establishes a hierarchy of cleanliness levels, with the most critical manufacturing areas maintained at the highest pressures. This cascade approach ensures that air always flows from cleaner to less clean areas, preventing contamination backflow. The pressure differential design must account for door opening frequencies, personnel movement patterns, and emergency scenarios that could disrupt normal airflow patterns.

Semiconductor cleanroom zoning best practices require integration of MAU systems with architectural design elements, including airlocks, pass-through chambers, and material handling areas. The system design must maintain pressure differentials under all operating conditions while providing adequate air changes to support manufacturing processes and personnel comfort.

Airflow Distribution and Velocity Control

Semiconductor cleanrooms utilize unidirectional airflow patterns to minimize particle residence time and prevent contamination accumulation. The MAU system must deliver air uniformly across the cleanroom ceiling while maintaining appropriate velocities for particle removal. Cleanroom airflow calculations determine the required supply air quantities based on cleanliness classification, room dimensions, and contamination generation rates.

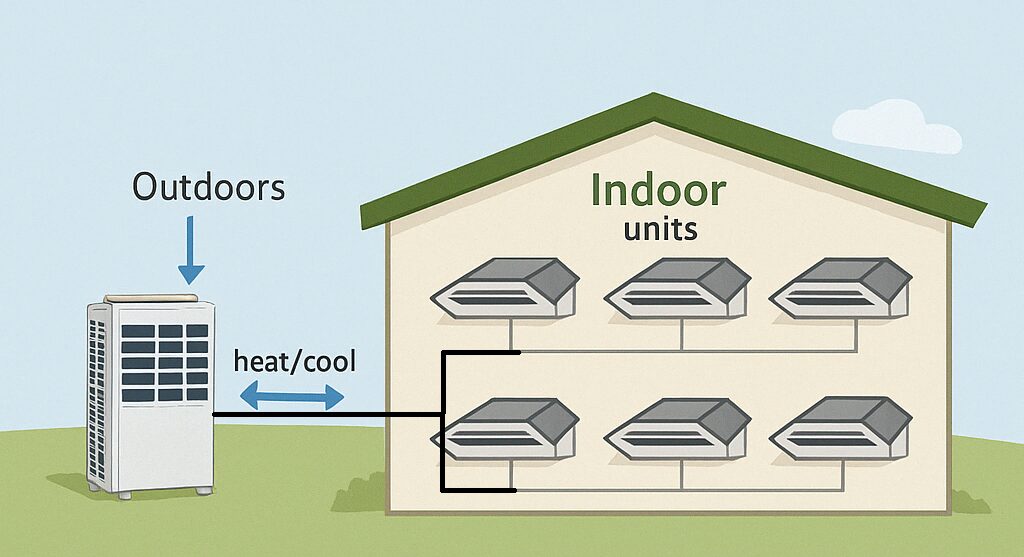

The airflow distribution system typically employs fan-filter units (FFUs) or central supply approaches, each with distinct advantages and limitations. FFU systems provide localized control and redundancy but require careful coordination to maintain uniform airflow patterns. Central supply systems offer greater energy efficiency and simplified maintenance but demand more complex ductwork distribution networks.

Velocity control becomes critical in areas where personnel work directly with sensitive products or equipment. The airflow must provide adequate contamination removal without creating excessive turbulence that could disturb manufacturing processes. Advanced computational fluid dynamics (CFD) modeling helps optimize airflow patterns and identify potential recirculation zones that could compromise cleanliness levels.

Energy Efficiency and Sustainability Considerations

Semiconductor MAU systems consume substantial amounts of energy, making efficiency optimization a critical design consideration. Energy efficient HVAC systems incorporate variable speed drives, economizer cycles, and heat recovery technologies to minimize operating costs while maintaining performance standards. The energy consumption must be balanced against cleanliness requirements to achieve optimal lifecycle cost performance.

Heat recovery systems capture waste heat from exhaust air streams and utilize it for preheating incoming makeup air. These systems can achieve significant energy savings, particularly in climates with extreme temperature differences between indoor and outdoor conditions. However, the heat recovery design must prevent any cross-contamination between exhaust and supply air streams through proper heat exchanger selection and installation practices.

Variable air volume (VAV) control strategies can reduce energy consumption during periods of reduced manufacturing activity while maintaining minimum airflow requirements for cleanliness maintenance. VAV system integration requires sophisticated control algorithms that monitor occupancy levels, equipment operation, and environmental conditions to optimize system performance continuously.

Control System Integration and Automation

Modern semiconductor MAU systems incorporate advanced building management systems (BMS) that provide comprehensive monitoring and control capabilities. BMS integration enables real-time optimization of system performance while maintaining detailed records of environmental conditions for quality assurance and regulatory compliance purposes. The control system must interface with manufacturing execution systems to coordinate environmental control with production schedules.

Automated alarm systems provide immediate notification of any deviations from specified operating parameters, enabling rapid response to prevent contamination events. The alarm hierarchy must distinguish between minor deviations that require attention and critical alarms that demand immediate action. Historical data logging capabilities support trend analysis and predictive maintenance strategies that minimize unexpected system failures.

Programmable logic controllers (PLCs) provide local control functions while interfacing with higher-level management systems. These controllers must operate reliably in industrial environments while providing the flexibility to accommodate changing process requirements and facility modifications over time.

Maintenance and Reliability Strategies

Semiconductor MAU systems require comprehensive maintenance programs to ensure continuous operation and optimal performance. Preventive maintenance strategies focus on filter replacement, component inspection, and system calibration to prevent unexpected failures that could compromise manufacturing operations. The maintenance schedule must balance component reliability with manufacturing uptime requirements.

Filter replacement procedures require careful planning to minimize disruption to manufacturing processes while ensuring continuous air quality. Some facilities incorporate redundant filtration systems that allow maintenance activities without shutting down production areas. The filter inventory management system must ensure adequate spare parts availability while minimizing storage costs and obsolescence risks.

System reliability depends on component selection, installation quality, and ongoing maintenance practices. Critical components often incorporate redundant configurations that provide backup capability during maintenance or failure events. The reliability analysis must consider both individual component failure rates and system-level dependencies that could affect overall performance.

Regulatory Compliance and Standards

Semiconductor MAU design must comply with multiple regulatory frameworks and industry standards that govern cleanroom construction and operation. Cleanroom classification standards including ISO 14644, Federal Standard 209E, and BIS IS 15518 establish specific requirements for air cleanliness, testing procedures, and monitoring protocols. These standards define the minimum performance criteria that MAU systems must achieve and maintain throughout their operational life.

International codes such as ASHRAE standards provide guidance on design methodologies, testing procedures, and operational practices for cleanroom environmental control systems. ASHRAE guidelines address energy efficiency requirements, indoor air quality standards, and safety considerations that impact MAU system design and operation. Compliance with these standards ensures that facilities meet regulatory requirements while achieving optimal performance.

Local building codes and environmental regulations may impose additional requirements that affect MAU system design and installation. These regulations often address fire safety, structural considerations, and environmental impact that must be integrated into the overall design approach. The regulatory compliance strategy must account for both initial certification requirements and ongoing monitoring obligations.

Future Trends and Innovations

The semiconductor industry continues to evolve toward smaller feature sizes and more complex manufacturing processes, driving demand for even more sophisticated MAU systems. Innovative cleanroom technologies incorporate artificial intelligence and machine learning algorithms to optimize system performance and predict maintenance requirements. These advanced systems can adapt to changing conditions automatically while maintaining optimal environmental control.

Artificial intelligence integration enables predictive maintenance strategies that identify potential problems before they impact manufacturing operations. AI-powered systems can analyze vast amounts of operational data to optimize energy consumption, predict component failures, and recommend system modifications that improve performance. This technology represents a significant advancement in cleanroom environmental control capabilities.

Sustainability initiatives drive development of more energy-efficient MAU systems that reduce environmental impact while maintaining performance standards. Green building certification programs encourage adoption of sustainable technologies and practices that minimize resource consumption and environmental impact. These initiatives influence MAU design approaches and component selection strategies.

FAQ

What are the key differences between semiconductor MAU systems and conventional HVAC systems?

Semiconductor MAU systems require ultra-high filtration efficiency, precise temperature and humidity control, and continuous operation without interruption. They incorporate multiple filtration stages, advanced control systems, and redundant components to prevent contamination that could damage semiconductor manufacturing processes.

How do you determine the required airflow capacity for a semiconductor cleanroom MAU system?

Airflow capacity depends on cleanroom classification, room dimensions, contamination generation rates, and heat load calculations. The system must provide sufficient air changes per hour to maintain cleanliness levels while accommodating process equipment exhaust requirements and maintaining proper pressure differentials.

What maintenance intervals are recommended for semiconductor MAU systems?

Filter replacement typically occurs every 6-12 months depending on loading conditions, while system calibration and component inspection should be performed quarterly. Critical components may require monthly inspection to ensure continuous operation and prevent unexpected failures.

How do you ensure energy efficiency in semiconductor MAU systems?

Energy efficiency can be achieved through variable speed drives, heat recovery systems, economizer cycles, and advanced control algorithms. The key is balancing energy consumption with cleanliness requirements to achieve optimal lifecycle cost performance.

What are the most common failure modes in semiconductor MAU systems?

Common failure modes include filter loading, control system malfunctions, component wear, and calibration drift. Preventive maintenance programs and redundant system designs help minimize the impact of these failures on manufacturing operations.

How do you validate the performance of a semiconductor MAU system?

Performance validation involves comprehensive testing of filtration efficiency, airflow patterns, temperature and humidity control, and pressure differentials. Testing must be conducted according to relevant standards and documented to demonstrate compliance with cleanroom requirements.

Disclaimer

The content here is intended solely for educational and informational purposes. All case studies, examples, and hypothetical scenarios are illustrative in nature and do not refer to, endorse, or represent any actual company, organization, or product. Any similarity to real-world entities or events is purely coincidental. Readers are encouraged to verify any technical details or operational recommendations with additional, independent research prior to implementation. The author and publisher assume no responsibility or liability for any errors, omissions, or outcomes resulting from the use of this material.

About the Author

Mr. Om Prakash, with over 18 years of hands-on experience in the HVAC industry, brings unmatched expertise in cleanroom, semiconductor, pharmaceutical, data center, commercial, and industrial HVAC systems. As the founder of HVAC Technocrat, he specializes in customized HVAC design, energy efficiency audits, retrofit planning, and turnkey consultancy services across India. He simplifies complex HVAC concepts and shares real-world insights to support professionals, facility managers, and decision-makers. For enquiries or project support, call or WhatsApp at +91 9908091942, email hvactechnocrats@gmail.com, or visit www.hvactechnocrat.com. Also, follow his LinkedIn profile.