Semiconductor cleanroom zoning represents the backbone of contamination control in modern chip manufacturing facilities. This systematic approach to space planning ensures that different manufacturing processes operate within their required cleanliness levels while preventing cross-contamination between zones. The concept extends far beyond simple room separation, incorporating sophisticated airflow management, pressure differentials, and material flow control mechanisms that collectively maintain the sterile environment essential for semiconductor production.

Understanding the Critical Role of Semiconductor Cleanroom Zoning

The importance of proper zoning becomes evident when considering that a single particle measuring just 0.1 micrometers can destroy an entire semiconductor wafer worth thousands of dollars. Indian semiconductor facilities, particularly those emerging under government initiatives like the Production Linked Incentive scheme, must implement robust zoning strategies to compete globally. These facilities typically handle everything from basic assembly operations to advanced wafer fabrication, each requiring distinct contamination control approaches that reflect international standards while adapting to local operational conditions.

Effective zoning strategies directly impact production yield, operational efficiency, and compliance with international standards such as ISO 14644-1 and various semiconductor industry specifications. The complexity increases when facilities must accommodate multiple product lines, different cleanliness requirements, and varying process technologies within a single building envelope. Understanding these fundamentals forms the foundation for developing comprehensive contamination control strategies.

Enjoying this content? Get expert HVAC updates on our Telegram Channel.

Wafer Fab Layout Optimization Through Strategic Zone Planning

Wafer fab layout optimization demands careful consideration of process flow, equipment placement, and personnel movement patterns to minimize contamination risks. The traditional approach involves creating a linear flow from raw wafer input through various processing steps to final testing and packaging. However, modern facilities often require more complex layouts that accommodate multiple process lines, shared utilities, and flexible manufacturing capabilities while maintaining strict contamination control.

The optimization process begins with mapping critical process steps and identifying contamination-sensitive operations. Photolithography areas typically require the highest cleanliness levels, often ISO Class 1 or Class 10, while mechanical assembly operations might function adequately in Class 1000 or Class 10000 environments. This hierarchy drives the overall facility layout, with the cleanest areas positioned at the facility core and progressively less critical zones arranged in concentric rings around this central clean zone.

Modern Indian semiconductor facilities increasingly adopt the ballroom concept, where large open cleanroom spaces house multiple process tools with flexible reconfiguration capabilities. This approach offers significant advantages in terms of airflow management, equipment access, and future expansion possibilities. The ballroom layout typically features a raised floor system for utilities distribution and a sophisticated ceiling-mounted air handling system that provides laminar airflow across the entire space.

Personnel and material flow patterns significantly influence layout optimization decisions. Successful designs incorporate separate pathways for people and materials, with dedicated airlocks, gowning areas, and decontamination stations positioned strategically throughout the facility. The goal involves minimizing travel distances while ensuring that all movements follow contamination control protocols. Advanced facilities implement automated material handling systems that further reduce human presence in the most critical zones.

Chip Manufacturing Area Segregation Principles

Chip manufacturing area segregation operates on the fundamental principle that different manufacturing processes generate varying types and levels of contamination. Wet chemical processes, plasma etching, ion implantation, and photolithography each present unique challenges that require specific containment and isolation strategies. Effective segregation ensures that contamination from one process does not compromise the cleanliness requirements of adjacent operations.

Chemical segregation represents one of the most critical aspects of area planning in semiconductor facilities. Wet benches handling hydrofluoric acid require specialized exhaust systems and corrosion-resistant materials, while organic solvent processes demand explosion-proof electrical systems and appropriate fire suppression measures. These chemical-specific requirements often drive the decision to create dedicated zones with their own air handling systems, preventing cross-contamination between incompatible processes.

Particle generation characteristics also influence segregation decisions. Mechanical processes such as wafer dicing, grinding, and packaging operations generate significantly more particles than chemical vapor deposition or photolithography processes. Facilities typically locate high-particle-generation processes in separate zones with enhanced air filtration and higher air change rates to contain contamination at its source.

Temperature and humidity requirements further complicate segregation planning. Photolithography processes often require precise temperature control within ±0.1°C, while furnace operations might tolerate broader temperature ranges. Humidity sensitivity varies dramatically between processes, with some requiring less than 1% relative humidity while others function adequately at standard cleanroom conditions of 45±5% RH. These environmental requirements often necessitate separate air handling systems for different zones.

Cleanroom Classification Zones and Compliance Requirements

Cleanroom classification zones must align with specific industry standards and product requirements while providing practical operational flexibility. The ISO 14644-1 standard provides the international framework for cleanroom classification, defining particle concentration limits for different cleanliness classes. Indian semiconductor facilities typically implement multiple classification zones within a single facility, ranging from ISO Class 1 for critical photolithography areas to ISO Class 8 for packaging and assembly operations.

The classification system considers both particle size and concentration, with measurements typically conducted using laser particle counters capable of detecting particles as small as 0.1 micrometers. Class 1 cleanrooms permit no more than 10 particles per cubic meter of 0.1-micrometer size, while Class 100 allows up to 3,520 particles of the same size per cubic meter. These stringent requirements demand sophisticated air filtration systems, typically employing HEPA or ULPA filters with 99.999% efficiency ratings.

Monitoring and verification requirements add another layer of complexity to classification zone management. Facilities must conduct regular particle counts, airflow measurements, and filter integrity tests to maintain certification. Indian facilities often face additional challenges related to external environmental conditions, including higher dust levels and seasonal variations that can impact cleanroom performance. Successful operations implement continuous monitoring systems that provide real-time data on particle levels, allowing for immediate corrective actions when deviations occur.

The transition zones between different classification areas require careful design attention to prevent contamination migration. These areas typically incorporate air locks, pressure cascades, and specialized air handling systems that maintain appropriate pressure differentials while allowing personnel and material movement. The pressure differential between adjacent zones should typically maintain at least 2.5 Pascals, with higher differentials used when significant cleanliness differences exist.

Fab Facility Space Planning for Optimal Contamination Control

Fab facility space planning integrates multiple engineering disciplines to create environments that support both current operations and future expansion needs. The planning process must consider structural requirements, utility distribution, equipment access, emergency egress, and contamination control measures within a cohesive design framework. Modern facilities typically allocate 60-70% of total floor area to production spaces, with the remainder dedicated to support functions including mechanical rooms, offices, and material storage areas.

The vertical organization of fab facilities significantly impacts contamination control effectiveness. Most facilities employ a three-level design with mechanical equipment located on the top floor, cleanroom production areas on the middle level, and utility distribution through a raised floor system at the bottom level. This arrangement facilitates gravity-fed exhaust systems, simplified utility routing, and effective separation of clean and potentially contaminated zones.

Utility distribution planning requires careful coordination to minimize contamination risks while providing necessary services to all areas. Chemical distribution systems typically utilize dedicated corridors or interstitial spaces to isolate potentially hazardous materials from production areas. Electrical systems must comply with explosion-proof requirements in certain zones while providing the clean, stable power required for sensitive semiconductor equipment.

Future flexibility considerations increasingly influence space planning decisions as semiconductor technology continues evolving rapidly. Facilities must accommodate equipment changes, process modifications, and capacity expansions without compromising contamination control integrity. This requirement often drives decisions toward larger open spaces with flexible utility connections rather than fixed, process-specific room layouts.

Advanced Airflow Management Systems in Zoned Environments

Advanced airflow management systems form the technical foundation of effective cleanroom zoning, providing the means to maintain required particle levels while accommodating complex facility layouts. These systems must deliver appropriate air volumes, maintain pressure differentials, provide uniform air distribution, and minimize energy consumption across multiple zones with varying requirements. Modern facilities typically employ computer-based airflow simulation during design phases to optimize system performance and identify potential problem areas.

Laminar airflow systems represent the gold standard for critical semiconductor processes, providing unidirectional airflow that sweeps particles away from sensitive areas. These systems typically operate at velocities between 0.3 and 0.5 meters per second, creating a laminar boundary layer that prevents turbulent mixing and particle recirculation. The implementation requires precision-engineered air distribution systems with HEPA or ULPA filtration, often consuming 30-40% of total facility energy.

Mixed airflow systems offer energy advantages in less critical areas while maintaining adequate contamination control. These systems combine high-efficiency filtration with strategic air distribution to achieve required particle levels at lower energy costs. The key involves understanding particle generation patterns and designing airflow systems that capture contamination at its source before it can spread throughout the space.

Pressure cascade management becomes critical when multiple zones with different cleanliness requirements connect within a single facility. The system must maintain appropriate pressure differentials across all boundaries while accommodating door openings, equipment installations, and normal operational activities. Advanced facilities implement automated pressure control systems that adjust airflow rates in real-time to maintain required differentials despite changing conditions.

Contamination Source Identification and Control Strategies

Contamination source identification requires systematic analysis of all potential particle and chemical sources within semiconductor facilities. Human activities typically represent the largest contamination source, with personnel generating particles through skin shedding, clothing fibers, and respiratory emissions. Equipment operations contribute mechanical particles, chemical residues, and electromagnetic interference that can impact sensitive processes. External sources including outdoor air, construction activities, and utility systems add additional contamination challenges.

Personnel contamination control strategies encompass comprehensive gowning procedures, training programs, and behavioral modifications designed to minimize particle generation. Modern facilities implement multi-stage gowning sequences with air showers, sticky mats, and ionization systems that remove particles and static charges before personnel enter critical areas. The effectiveness depends heavily on employee training and adherence to established procedures, making ongoing education programs essential for maintaining contamination control standards.

Equipment-related contamination control focuses on both source elimination and containment strategies. Preventive maintenance programs help minimize particle generation from mechanical wear, while specialized enclosures contain contamination from high-particle-generation processes. Advanced facilities implement real-time particle monitoring systems that automatically adjust air filtration rates when equipment-generated contamination exceeds predetermined thresholds.

Chemical contamination presents unique challenges requiring specialized detection and control strategies. Outgassing from construction materials, cleaning solvents, and process chemicals can create molecular contamination that interferes with semiconductor processes even at extremely low concentrations. Facilities typically implement material selection programs, bake-out procedures, and specialized filtration systems designed to remove molecular contaminants from the cleanroom environment.

Environmental Control Integration Across Multiple Zones

Environmental control integration demands sophisticated coordination between temperature, humidity, pressure, and air quality management systems across multiple zones with varying requirements. The complexity increases when facilities must accommodate incompatible environmental conditions within adjacent spaces while maintaining energy efficiency and operational flexibility. Modern systems typically employ computer-based control strategies that optimize performance across all zones simultaneously rather than treating each area independently.

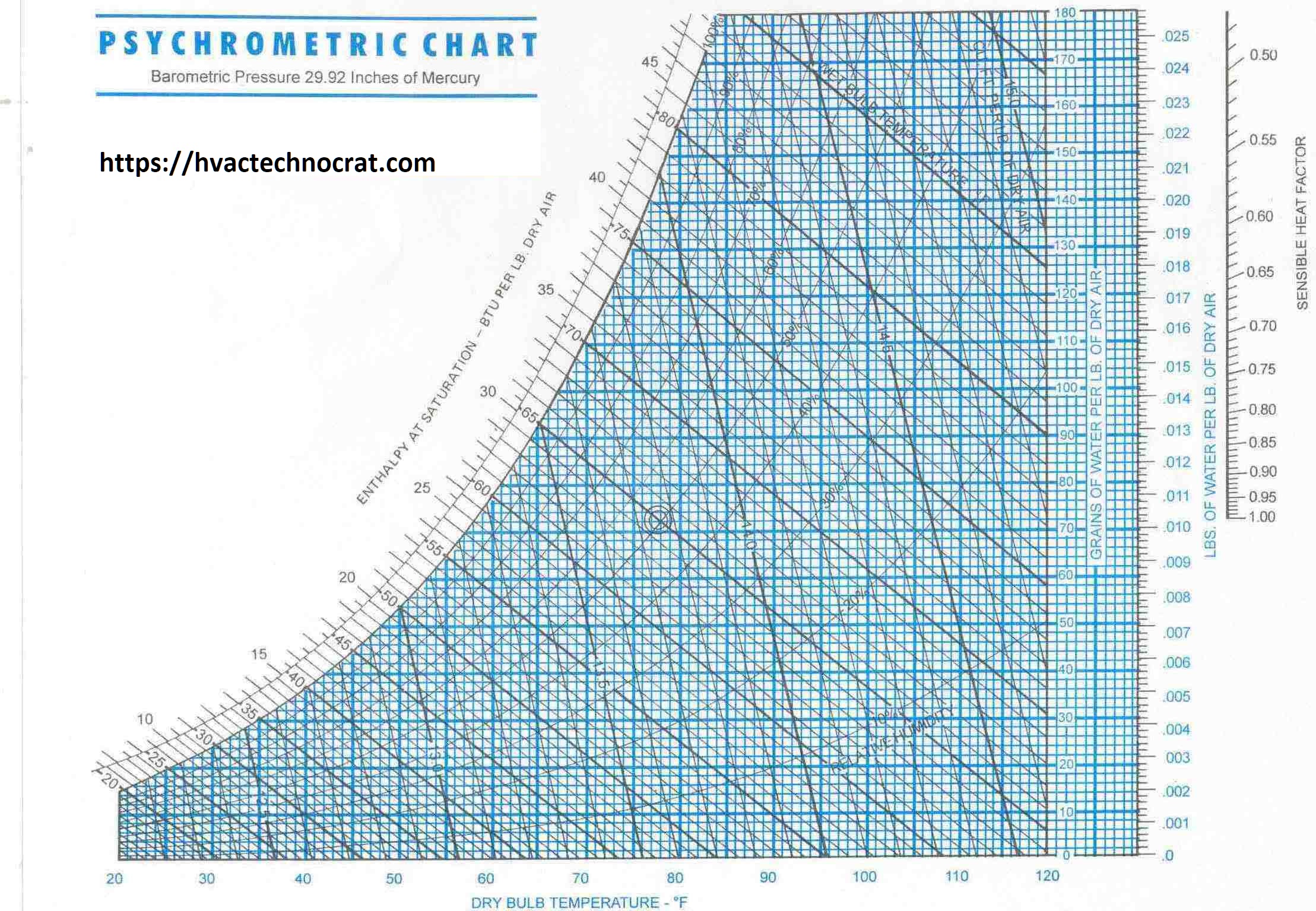

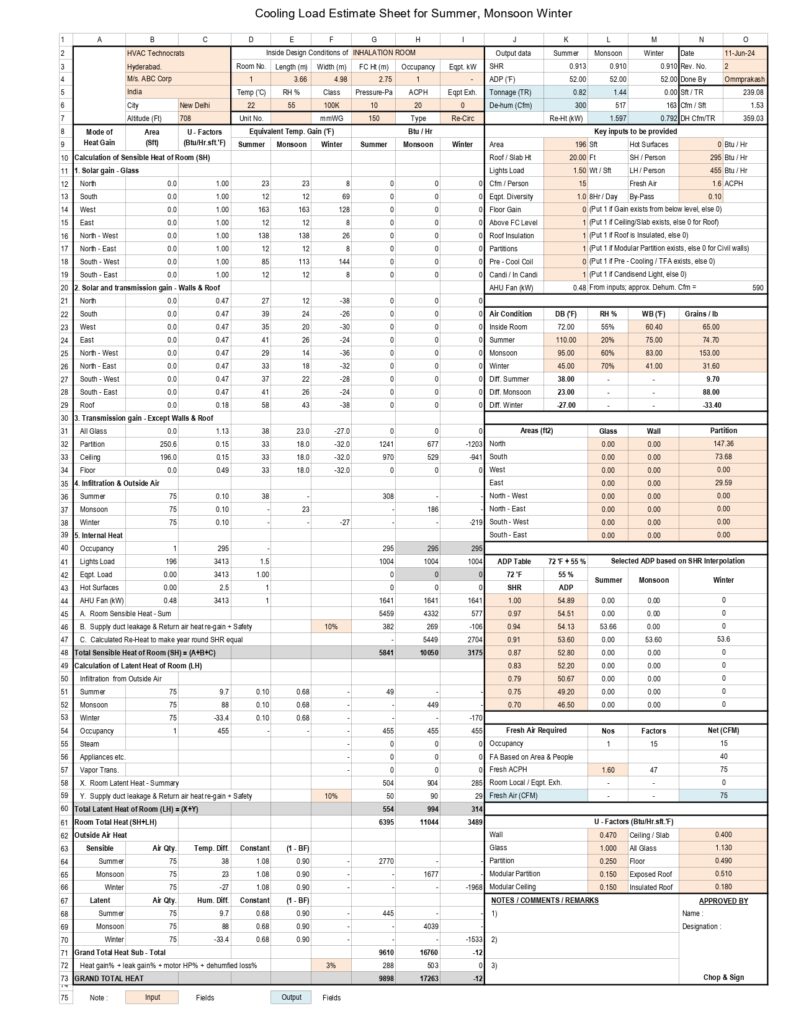

Temperature control strategies must address both sensible and latent heat loads while maintaining the precision required for semiconductor processes. Critical photolithography areas often require temperature stability within ±0.1°C, while general manufacturing areas might tolerate ±1°C variations. The challenge involves designing systems that provide required precision in critical areas without overconditioning less sensitive zones, which would waste energy and create operational inefficiencies.

Humidity control becomes particularly challenging in facilities with multiple zones requiring different moisture levels. Photolithography processes typically require very low humidity levels to prevent resist adhesion problems, while some chemical processes function better at moderate humidity levels that reduce static electricity generation. The solution often involves dedicated air handling systems for each zone with different humidity requirements, coupled with sophisticated moisture management strategies.

Integration challenges extend beyond basic environmental parameters to include air quality management, pressure control, and emergency response capabilities. Systems must coordinate responses to equipment failures, power outages, and other emergency conditions while maintaining contamination control integrity. Advanced facilities implement redundant systems and fail-safe operating modes that ensure critical areas remain protected even during equipment failures or maintenance activities.

Technology Integration for Smart Cleanroom Operations

Technology integration transforms traditional cleanroom operations through automation, real-time monitoring, and predictive maintenance capabilities that enhance contamination control effectiveness while reducing operational costs. Modern facilities typically implement integrated building management systems that coordinate HVAC operations, particle monitoring, access control, and emergency response functions through centralized control platforms. These systems provide operators with comprehensive facility status information and automated responses to changing conditions.

Sensor networks enable continuous monitoring of critical parameters including particle levels, temperature, humidity, pressure differentials, and chemical concentrations throughout the facility. Advanced systems employ wireless sensor networks that eliminate potential contamination sources associated with traditional wiring while providing flexible monitoring capabilities that can adapt to changing facility layouts. The data collected supports both real-time operational decisions and long-term performance optimization strategies.

Artificial intelligence applications increasingly support cleanroom operations through predictive maintenance programs, energy optimization algorithms, and contamination source identification systems. Machine learning algorithms analyze historical performance data to identify patterns that predict equipment failures, optimize filter replacement schedules, and recommend operational adjustments that improve contamination control effectiveness. These capabilities become particularly valuable in large facilities with complex interconnected systems.

Digital twin technology represents the latest advancement in cleanroom management, creating virtual facility models that support operational optimization, staff training, and scenario planning activities. These models incorporate real-time sensor data, equipment performance information, and environmental conditions to provide accurate representations of facility operations. Operators can use digital twins to test operational changes, train personnel, and optimize system performance without impacting actual production operations.

Energy Efficiency Considerations in Multi-Zone Design

Energy efficiency considerations significantly impact the economic viability of semiconductor cleanroom operations, with HVAC systems typically consuming 40-60% of total facility energy. Multi-zone designs offer opportunities for optimization through load matching, equipment right-sizing, and operational scheduling strategies that reduce energy consumption while maintaining required environmental conditions. The key involves understanding the relationship between contamination control requirements and energy consumption to identify optimization opportunities.

Heat recovery systems provide significant energy savings opportunities in facilities with simultaneous heating and cooling requirements. Many semiconductor processes generate substantial heat loads that must be removed from cleanroom areas, while other areas require heating during certain operational periods. Heat recovery systems capture waste heat from exhaust airstreams and use it to condition incoming fresh air, reducing both heating and cooling energy requirements.

Variable air volume systems enable energy optimization by adjusting airflow rates based on actual contamination control requirements rather than maintaining constant maximum flow rates. These systems typically incorporate real-time particle monitoring that automatically adjusts air change rates when contamination levels change. During periods of reduced activity, such as overnight or weekend operations, airflow rates can be reduced significantly while maintaining required cleanliness levels.

Equipment optimization strategies focus on improving the efficiency of individual system components including fans, pumps, chillers, and air handling units. Modern facilities typically employ high-efficiency equipment with variable speed drives that adjust operating parameters based on actual load requirements. Regular maintenance programs ensure equipment operates at peak efficiency, while equipment replacement programs systematically upgrade older, less efficient components.

Regulatory Compliance and Industry Standards

Regulatory compliance requirements significantly influence cleanroom zoning decisions, with facilities must meeting various national and international standards depending on their products and markets. Indian semiconductor facilities typically must comply with BIS standards, ISHRAE guidelines, international ISO standards, and specific customer requirements that may impose additional restrictions. The complexity increases when facilities serve multiple markets with different regulatory requirements.

ISO 14644-1 provides the primary international framework for cleanroom classification and testing procedures. This standard defines particle concentration limits for different cleanliness classes while specifying testing methods, monitoring frequencies, and certification requirements. Facilities must demonstrate compliance through regular testing programs that document particle levels, airflow rates, and filter performance across all classified areas.

ASHRAE standards provide guidance on HVAC system design, operation, and maintenance practices that support cleanroom applications. These standards address air filtration requirements, energy efficiency considerations, and indoor air quality management strategies that complement ISO cleanroom standards. The integration of multiple standards requires careful coordination to ensure all requirements are met without creating conflicting operational constraints.

Industry-specific standards add another layer of complexity, with semiconductor manufacturers often imposing requirements that exceed general cleanroom standards. These specifications typically address specific contamination concerns related to particular manufacturing processes, materials compatibility requirements, and quality assurance procedures that support high-yield production operations. Facilities serving multiple customers may need to accommodate different standards simultaneously within the same building.

Future Trends and Emerging Technologies

Future trends in semiconductor cleanroom zoning reflect ongoing advances in manufacturing technology, environmental control systems, and automation capabilities that promise to improve contamination control effectiveness while reducing operational costs. The industry continues moving toward smaller feature sizes and more complex manufacturing processes that demand increasingly sophisticated contamination control strategies. These trends drive innovations in facility design, equipment technology, and operational procedures.

Nanotechnology applications are emerging in air filtration systems, offering improved particle removal efficiency and lower pressure drops compared to traditional HEPA and ULPA filters. These advanced filtration media employ nanofiber technology that creates smaller pore sizes while maintaining high airflow rates. The technology promises significant energy savings while providing superior contamination control performance.

Advanced monitoring technologies including real-time molecular contamination detection, automated particle sizing, and wireless sensor networks provide unprecedented visibility into cleanroom performance. These systems enable proactive contamination control strategies that identify and address problems before they impact production operations. The integration with artificial intelligence algorithms supports predictive maintenance programs and operational optimization strategies that improve overall facility performance.

Sustainable design principles increasingly influence cleanroom development, with facilities incorporating renewable energy systems, water recycling programs, and waste minimization strategies that reduce environmental impact while maintaining required performance levels. These approaches align with corporate sustainability goals while potentially reducing operational costs through resource conservation and efficiency improvements.

Frequently Asked Questions

How to control contamination in a clean room?

Contamination control in cleanrooms requires a comprehensive approach combining advanced air filtration, positive pressure maintenance, strict personnel protocols, and regular monitoring. The primary strategy involves creating laminar airflow patterns that continuously remove particles while preventing external contamination entry through pressure cascades and airlocks.

What does class 100 and class 1000 clean room mean?

Class 100 cleanrooms allow maximum 100 particles of 0.5 micrometers per cubic foot, equivalent to ISO Class 5. Class 1000 permits up to 1000 particles of the same size, corresponding to ISO Class 6. These classifications define the maximum allowable particle concentrations for different manufacturing processes.

What are the clean room standards for semiconductors?

Semiconductor cleanroom standards primarily follow ISO 14644-1 for classification, with specific areas requiring ISO Class 1-5 depending on process sensitivity. Additional standards include SEMI specifications for equipment, ASHRAE guidelines for HVAC systems, and industry-specific requirements for molecular contamination control and electrostatic discharge protection.

How does a cleanroom primarily prevent contamination?

Cleanrooms prevent contamination through engineered airflow systems that create positive pressure environments with continuous air filtration. HEPA or ULPA filters remove particles while laminar airflow patterns sweep contaminants away from sensitive areas. Personnel protocols and material control procedures minimize contamination introduction.

What is the clean room market for semiconductors?

The global semiconductor cleanroom market is experiencing rapid growth, particularly in Asia-Pacific regions including India. Market expansion is driven by increasing semiconductor demand, advanced manufacturing technologies, and government initiatives supporting domestic chip production. The market encompasses construction, equipment, and ongoing operational services.

What are the key factors in cleanroom zone design?

Key factors include process compatibility, contamination sensitivity levels, personnel and material flow patterns, utility requirements, regulatory compliance needs, and future flexibility requirements. Successful designs integrate these factors while optimizing energy efficiency and operational costs throughout the facility lifecycle.

Disclaimer

The content here is intended solely for educational and informational purposes. All case studies, examples, and hypothetical scenarios are illustrative in nature and do not refer to, endorse, or represent any actual company, organization, or product. Any similarity to real-world entities or events is purely coincidental. Readers are encouraged to verify any technical details or operational recommendations with additional, independent research prior to implementation. The author and publisher assume no responsibility or liability for any errors, omissions, or outcomes resulting from the use of this material.

About the Author

Mr. Om Prakash, with over 18 years of hands-on experience in the HVAC industry, brings unmatched expertise in cleanroom, semiconductor, pharmaceutical, data center, commercial, and industrial HVAC systems. As the founder of HVAC Technocrat, he specializes in customized HVAC design, energy efficiency audits, retrofit planning, and turnkey consultancy services across India. He simplifies complex HVAC concepts and shares real-world insights to support professionals, facility managers, and decision-makers. For enquiries or project support, call or WhatsApp at +91 9908091942, email hvactechnocrats@gmail.com, or visit www.hvactechnocrat.com. Also, follow his LinkedIn profile.