What is Cooling Tower in HVAC Systems

A cooling tower is a specialized heat rejection device that extracts waste heat to the atmosphere through the cooling of a water stream to a lower temperature. It plays a crucial role in HVAC (Heating, Ventilation, and Air Conditioning) systems and industrial processes where large amounts of heat need to be dissipated efficiently.

Cooling towers work on the principle of evaporation, where warm water from industrial processes or air conditioning systems is pumped to the top of the tower and distributed over the tower fill or packing. As this water cascades down through the fill material, it comes into contact with a stream of air moving upward through the tower. This air, usually induced by a fan, causes a small portion of the water to evaporate, which removes heat from the remaining water. The cooled water is then collected at the bottom of the tower and recirculated back into the system.

Cooling towers are classified into various types based on their design and application, such as crossflow, counterflow, and hybrid configurations, each offering specific advantages in different industrial and HVAC settings.

Basics of Cooling Tower

A cooling tower is an essential component in HVAC and industrial processes for dissipating heat from water to the atmosphere. It operates on the principle of evaporative cooling, where warm water from processes or air conditioning systems is circulated to the top of the tower and distributed over a packing material. As this water flows down, it comes into contact with a rising air stream induced by fans. Some of the water evaporates, absorbing heat and cooling the rest of the water. The cooled water collects at the bottom of the tower and is recirculated back into the system.

Cooling towers vary in design, including crossflow and counterflow configurations. Crossflow towers direct the water flow horizontally across the vertical air flow, while counterflow towers direct water vertically downward against the upward air flow, maximizing heat transfer efficiency. These towers are crucial for maintaining optimal temperatures in industrial processes and HVAC systems, enhancing efficiency and reducing energy consumption.

Role and Importance of Cooling Towers in HVAC Systems

Cooling towers play a crucial role in HVAC systems, providing essential heat removal for industrial and commercial applications. By understanding their function and impact, we can appreciate how they enhance energy efficiency and maintain optimal temperatures. This article delves into various aspects of cooling towers, addressing common questions and providing a comprehensive overview for HVAC professionals and enthusiasts.

What is the role of a cooling tower in HVAC systems?

Cooling towers in HVAC systems serve to remove excess heat from a building or industrial process by using water to transfer heat to the atmosphere. This process is essential in maintaining efficient operation and optimal temperatures within HVAC systems. By cooling the water that circulates through the HVAC system, cooling towers help to dissipate heat generated by air conditioning units, industrial equipment, or processes. This not only prevents overheating but also ensures that the HVAC system operates efficiently, reducing energy consumption and operational costs. Cooling towers are integral in managing heat load, making them indispensable in various applications, from commercial buildings to industrial facilities.

Why are cooling towers essential for HVAC applications?

Cooling towers are essential for HVAC applications because they significantly enhance energy efficiency and cooling performance. They achieve this by using the natural process of evaporation to dissipate heat from the water, which is more energy-efficient compared to other cooling methods. Cooling towers are particularly effective in large-scale HVAC applications, where traditional air-cooled systems might struggle to manage the heat load. By reducing the temperature of the water used in the HVAC system, cooling towers ensure that air conditioning units and other components can operate more efficiently, leading to lower energy consumption and costs. This makes them vital for maintaining comfortable indoor environments in commercial and industrial settings.

How do cooling towers contribute to energy efficiency in buildings?

Cooling towers contribute to energy efficiency in buildings by leveraging the evaporative cooling process to remove heat from the water used in HVAC systems. This process requires less energy compared to traditional air-cooled systems, resulting in significant energy savings. By maintaining lower water temperatures, cooling towers ensure that HVAC components, such as chillers and air conditioning units, operate more efficiently. This reduces the overall energy consumption of the building’s cooling system. Additionally, cooling towers can be integrated with energy management systems to optimize their performance, further enhancing energy efficiency and reducing operational costs. Their ability to effectively manage heat load makes them a key component in sustainable building design.

When should you consider using a cooling tower in HVAC designs?

Consider using a cooling tower in HVAC designs when dealing with large-scale applications that require efficient heat removal, such as commercial buildings, industrial facilities, or data centers. Cooling towers are particularly beneficial in environments with high cooling loads, where traditional air-cooled systems may be insufficient. They are also ideal for applications where energy efficiency is a priority, as they can significantly reduce energy consumption compared to other cooling methods. Additionally, cooling towers are suitable for locations with abundant water supply, as they rely on water for the evaporative cooling process. When planning HVAC designs, evaluate the specific cooling requirements and environmental factors to determine if a cooling tower is the best solution.

Where are cooling towers typically located within HVAC systems?

Cooling towers are typically located outside the main building structure, often on the rooftop or in a designated mechanical yard. Their placement is strategic to facilitate the release of heat into the atmosphere and to minimize the impact of noise and water vapor plumes on the building’s occupants. The location should also allow for easy access for maintenance and inspections. In some cases, cooling towers can be installed at ground level or in a central utility plant, depending on the layout and space constraints of the facility. Proper placement is crucial to ensure efficient operation and integration with the overall HVAC system, including the water circulation network and supporting infrastructure.

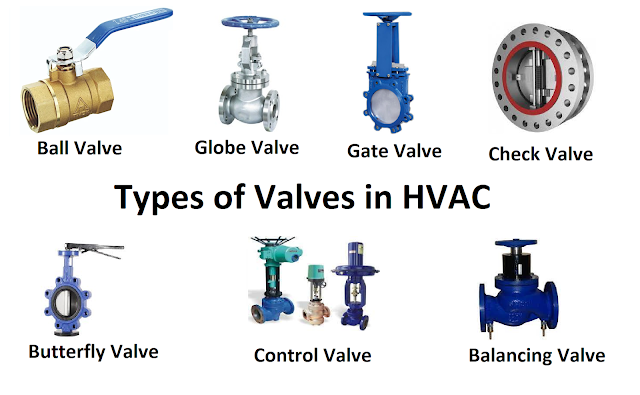

What are the different types of cooling towers used in HVAC applications?

Several types of cooling towers are used in HVAC applications, each with distinct features and benefits. The main types include:

- Natural Draft Cooling Towers: These rely on the natural convection of air to move through the tower and cool the water.

- Mechanical Draft Cooling Towers: These use fans to force air through the tower, providing more control over airflow and cooling efficiency. Mechanical draft towers are further categorized into forced draft and induced draft.

- Crossflow Cooling Towers: In these towers, water flows vertically while air flows horizontally through the fill media, providing efficient heat transfer.

- Counterflow Cooling Towers: In these towers, water flows downward while air flows upward, maximizing contact time for heat transfer.

- Hybrid Cooling Towers: These combine features of both wet and dry cooling towers to optimize performance and energy efficiency in varying conditions.

Each type has specific applications and advantages, making them suitable for different HVAC needs and environmental conditions.

How do evaporative cooling towers compare to dry cooling towers?

Evaporative cooling towers and dry cooling towers differ primarily in their cooling mechanisms and efficiency. Evaporative cooling towers use water evaporation to remove heat from the circulating water, which is highly efficient and effective in cooling large volumes of water. This method is energy-efficient and ideal for applications requiring significant cooling capacity. However, it does require a consistent water supply and regular maintenance to manage water quality and scaling.

Dry cooling towers, on the other hand, use air to cool the water without evaporation, relying on heat exchange through finned tubes or coils. While dry cooling towers are less efficient than evaporative towers, they have the advantage of not requiring water, making them suitable for areas with water scarcity or where water conservation is a priority. They also have lower maintenance requirements related to water treatment. The choice between the two depends on specific cooling needs, environmental conditions, and resource availability.

Why choose a crossflow cooling tower over a counterflow design?

Choosing a crossflow cooling tower over a counterflow design depends on several factors, including space constraints, efficiency requirements, and maintenance considerations. Crossflow cooling towers have a horizontal air flow that crosses the downward flow of water, allowing for easy access to internal components and simplified maintenance. This design typically requires less fan power and is quieter, making it suitable for applications where noise levels are a concern.

Counterflow cooling towers, with their upward air flow against the downward water flow, offer higher efficiency due to increased contact time between air and water. However, they can be more challenging to maintain because of the compact design and less accessible internal components. Crossflow towers are often preferred in situations where ease of maintenance and lower noise levels are priorities, while counterflow towers are chosen for applications requiring maximum cooling efficiency and where space is not a significant constraint.

When is it suitable to use a hybrid cooling tower in industrial settings?

Hybrid cooling towers are suitable for industrial settings that experience varying cooling loads and environmental conditions. These towers combine the benefits of both wet and dry cooling, allowing them to operate efficiently in diverse climates. They are particularly advantageous in regions with significant seasonal temperature variations, as they can switch between wet and dry modes to optimize performance and energy efficiency.

Hybrid cooling towers are also ideal for industrial processes that generate high heat loads but require flexible cooling solutions to manage water usage and operational costs. By utilizing dry cooling during cooler periods and evaporative cooling during hotter periods, hybrid towers reduce water consumption and maintain high cooling efficiency year-round. This makes them a valuable option for industries prioritizing sustainability and operational adaptability.

Where are induced draft cooling towers commonly installed in HVAC systems?

Induced draft cooling towers are commonly installed in HVAC systems for large commercial buildings, industrial facilities, and power plants. These towers use a fan located at the top to draw air through the system, ensuring efficient heat transfer and cooling performance. Their design allows for better control of air flow and cooling capacity, making them suitable for applications with high cooling demands.

In HVAC systems, induced draft cooling towers are typically installed on rooftops or in mechanical yards, where they can efficiently release heat into the atmosphere. Their placement is strategic to minimize noise and water vapor impact on the building and its occupants. Induced draft towers are also preferred in installations where space is limited, as their vertical design requires a smaller footprint compared to other cooling tower types.

What are the key applications of cooling towers in industrial processes?

Cooling towers play a vital role in various industrial processes, providing essential heat dissipation to maintain optimal operating conditions. Key applications include:

- Power Generation: Cooling towers are used in power plants to remove excess heat from steam condensers, ensuring efficient electricity production.

- Chemical Manufacturing: In chemical plants, cooling towers dissipate heat generated by exothermic reactions and equipment, maintaining safe and efficient operations.

- Oil and Gas Refining: Cooling towers help manage heat loads in refineries, ensuring efficient processing and preventing equipment overheating.

- Food and Beverage Production: Cooling towers are used to control temperatures in food processing, fermentation, and refrigeration systems.

- HVAC Systems: In large commercial buildings and data centers, cooling towers provide critical cooling for air conditioning systems and IT equipment.

These applications highlight the versatility and importance of cooling towers in maintaining efficient and safe industrial operations.

How are cooling towers used in power plants and manufacturing facilities?

Cooling towers in power plants and manufacturing facilities are used to manage heat loads and maintain optimal operating temperatures for various processes and equipment. In power plants, cooling towers remove excess heat from steam condensers, allowing efficient electricity generation and preventing equipment damage from overheating. This process involves circulating water through the condenser, where it absorbs heat, and then passing it through the cooling tower to dissipate the heat into the atmosphere.

In manufacturing facilities, cooling towers are used to cool machinery, processes, and products, ensuring efficient operation and product quality. They manage heat loads generated by industrial processes, such as chemical reactions, metalworking, and food processing. By maintaining proper cooling, these facilities can operate safely and efficiently, reducing energy consumption and operational costs. The use of cooling towers in these settings highlights their critical role in industrial and power generation applications.

Why are fiberglass cooling towers preferred in corrosive environments?

Fiberglass cooling towers are preferred in corrosive environments due to their excellent resistance to chemical corrosion, which ensures long-term durability and reliability. Unlike traditional cooling towers made of metal, fiberglass towers are impervious to rust and corrosion caused by harsh chemicals, saltwater, and other corrosive substances commonly found in industrial settings. This makes them ideal for use in chemical plants, coastal areas, and other environments where corrosion is a significant concern.

Additionally, fiberglass cooling towers are lightweight, easy to install, and require minimal maintenance compared to their metal counterparts. Their non-corrosive nature reduces the need for frequent repairs and replacements, resulting in lower maintenance costs and extended service life. The durability and corrosion resistance of fiberglass cooling towers make them a cost-effective and reliable choice for challenging environments where traditional materials may fail.

What are the specifications to consider when selecting a cooling tower?

When selecting a cooling tower, several key specifications should be considered to ensure optimal performance and suitability for the application. These include:

- Cooling Capacity: Determine the cooling load and select a tower that can handle the required heat rejection.

- Flow Rate: Consider the water flow rate needed to achieve the desired cooling effect.

- Temperature Range: Assess the entering and leaving water temperatures to ensure the tower can meet the cooling requirements.

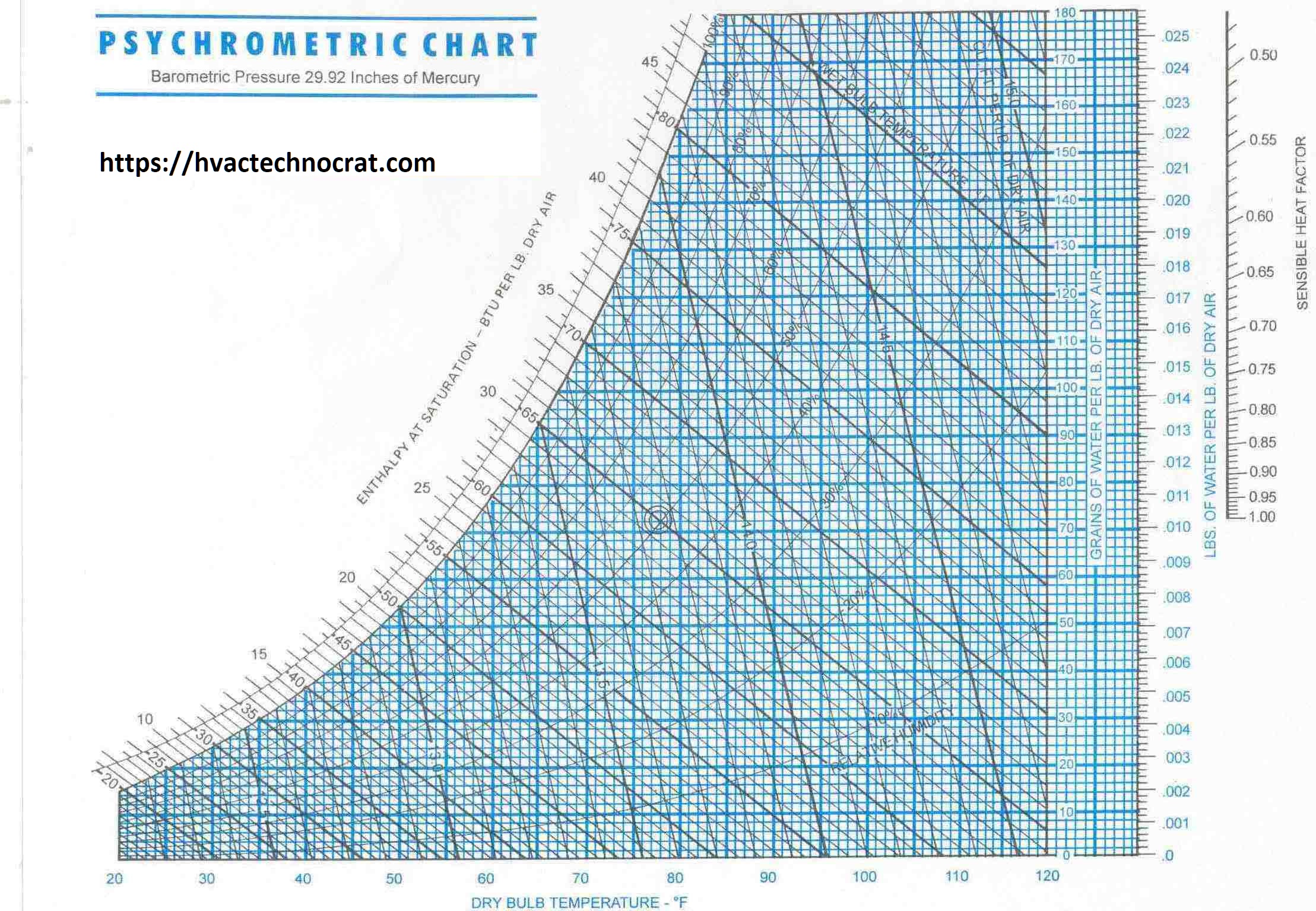

- Ambient Wet Bulb Temperature: The lowest temperature air can reach by evaporating water, crucial for determining cooling efficiency and tower performance.

- Energy Efficiency: Look for towers with high energy efficiency ratings to reduce operational costs.

- Material: Choose materials that are resistant to corrosion and suitable for the specific environmental conditions.

- Noise Levels: Consider the noise output, especially in residential or noise-sensitive areas.

- Footprint: Evaluate the available space for installation and select a tower with an appropriate size and design.

These specifications help ensure that the selected cooling tower meets the operational needs and environmental constraints of the application.

How does the capacity of a cooling tower affect its performance?

The capacity of a cooling tower directly affects its performance by determining the amount of heat it can dissipate. Cooling tower capacity is typically measured in tons or BTUs per hour, representing the amount of heat removed from the water. A higher-capacity cooling tower can handle larger heat loads, making it suitable for applications with significant cooling demands, such as industrial processes, power plants, and large commercial buildings.

If a cooling tower is undersized for the application, it will struggle to maintain the desired water temperature, leading to inefficient operation and potential overheating of equipment. Conversely, an oversized cooling tower may result in higher initial costs and unnecessary energy consumption. Therefore, accurately calculating the cooling load and selecting a tower with the appropriate capacity is crucial for efficient performance and cost-effective operation. Proper capacity selection ensures optimal cooling, energy efficiency, and system reliability.

Why is drift loss a critical specification in cooling tower selection?

Drift loss is a critical specification in cooling tower selection because it represents the amount of water that escapes the tower as droplets carried by the airflow. This water loss can lead to increased water consumption and potential environmental concerns, especially in areas with water scarcity or strict environmental regulations. Minimizing drift loss is essential to conserve water and reduce operational costs associated with water treatment and replenishment.

Cooling towers are designed with drift eliminators to capture and return the water droplets, reducing drift loss to acceptable levels. When selecting a cooling tower, it is important to consider the efficiency of these drift eliminators and ensure that the tower complies with industry standards for drift loss. Lower drift loss not only conserves water but also minimizes the impact on surrounding areas, preventing potential issues related to water damage and contamination. Therefore, evaluating and selecting a cooling tower with minimal drift loss is crucial for sustainable and efficient operation.

When should you consider the noise level rating of a cooling tower?

Consider the noise level rating of a cooling tower when it is installed in or near residential areas, office buildings, or noise-sensitive environments. Cooling towers can generate significant noise due to the operation of fans, water flow, and other mechanical components. Excessive noise can disrupt the surrounding environment, leading to complaints and potential regulatory issues.

To address this, manufacturers provide noise level ratings for their cooling towers, measured in decibels (dB). When selecting a cooling tower, it is important to choose one with an appropriate noise level rating that meets local noise regulations and minimizes disturbance to occupants and neighbors. Additionally, noise reduction features such as sound attenuators, quieter fan designs, and vibration dampening measures can be implemented to further reduce noise levels. Considering noise level ratings is essential for maintaining a harmonious and compliant installation, particularly in urban or densely populated areas.

Where can you find technical data sheets for different cooling tower models?

Technical data sheets for different cooling tower models can be found on the manufacturers’ websites, where they provide detailed information about the specifications, performance, and features of their products. These data sheets typically include key parameters such as cooling capacity, water flow rates, temperature ranges, dimensions, and materials of construction. They also provide information on energy efficiency, noise levels, and compliance with industry standards.

In addition to manufacturers’ websites, technical data sheets can be obtained from industry associations and organizations such as ASHRAE (https://ashrae.org/) and ISHRAE (https://ishrae.in/), which often publish guidelines and standards for cooling tower performance and selection. Consulting these resources ensures that you have accurate and comprehensive information to make informed decisions when selecting and designing cooling tower systems for specific applications.

What information is typically included in a cooling tower’s technical data sheet?

A cooling tower’s technical data sheet typically includes comprehensive information about the tower’s specifications, performance, and operational parameters. Key information often includes:

- Cooling Capacity: The amount of heat the tower can dissipate, usually measured in tons or BTUs per hour.

- Water Flow Rate: The rate at which water circulates through the tower, measured in gallons per minute (GPM).

- Temperature Range: The entering and leaving water temperatures.

- Dimensions: Physical dimensions of the tower, including height, width, and footprint.

- Materials: Materials of construction for the tower components, such as fill media, basin, and casing.

- Energy Efficiency: Efficiency ratings, including power consumption and performance metrics.

- Noise Levels: Noise output, typically measured in decibels (dB).

- Compliance: Compliance with industry standards and certifications.

This detailed information helps engineers and designers select the appropriate cooling tower for their specific application, ensuring optimal performance and efficiency.

How can you interpret performance data from a cooling tower’s specifications?

Interpreting performance data from a cooling tower’s specifications involves understanding key parameters and how they relate to the tower’s efficiency and suitability for a given application. Performance data typically includes cooling capacity, water flow rate, temperature range, and energy efficiency ratings.

- Cooling Capacity: Indicates the heat dissipation capability, measured in tons or BTUs per hour. Ensure the capacity matches the cooling load requirements.

- Water Flow Rate: The volume of water circulating through the tower, measured in GPM. Adequate flow rates are necessary for efficient heat transfer.

- Temperature Range: Specifies the entering and leaving water temperatures. Ensure the tower can achieve the desired cooling performance.

- Energy Efficiency: Efficiency ratings, such as Coefficient of Performance (COP) or Energy Efficiency Ratio (EER), indicate the tower’s energy consumption relative to its cooling output.

By analyzing these parameters, engineers can determine if the cooling tower meets the application’s requirements, ensuring efficient and effective cooling performance.

Why is compliance with codes and standards crucial for cooling tower installations?

Compliance with codes and standards is crucial for cooling tower installations to ensure safety, reliability, and environmental responsibility. Industry standards, such as those from ASHRAE (https://ashrae.org/) and ISHRAE (https://ishrae.in/), provide guidelines for design, construction, and performance, helping to maintain consistent quality and operational efficiency.

Compliance with these standards ensures that cooling towers meet specific requirements for structural integrity, energy efficiency, water usage, and environmental impact. Adhering to codes and standards also reduces the risk of operational failures, accidents, and legal issues, as it ensures that the installation follows best practices and regulatory requirements. By prioritizing compliance, engineers and facility managers can achieve safe, efficient, and sustainable cooling tower operations.

When should you consult with a professional regarding cooling tower codes and standards?

Consult with a professional regarding cooling tower codes and standards during the design, installation, and maintenance phases of a cooling tower project. Professional engineers and consultants can provide expert guidance on selecting the appropriate cooling tower type, ensuring compliance with industry standards, and addressing specific operational requirements.

During the design phase, professionals can help determine the cooling load, select suitable materials, and ensure the cooling tower meets energy efficiency and environmental regulations. During installation, they can oversee the process to ensure proper integration with the HVAC system and adherence to safety codes. Regular consultation with professionals during maintenance helps identify potential issues, ensure continued compliance, and optimize performance. Engaging with experts at these critical stages ensures a successful and compliant cooling tower installation.

What are the general arrangement drawings for cooling tower installations?

General arrangement drawings for cooling tower

installations provide detailed visual representations of the tower’s placement, components, and connections within the HVAC system. These drawings include top views, side views, and sectional views, illustrating the spatial relationships between the cooling tower, piping, pumps, valves, and other system components.

These drawings help engineers and contractors understand the layout and ensure proper installation and integration with the overall HVAC system. They also provide critical information on dimensions, clearances, and access points, facilitating efficient construction and maintenance. General arrangement drawings serve as essential tools for planning, communication, and execution of cooling tower projects, ensuring accurate and effective installation.

How do schematic drawings assist in understanding cooling tower systems?

Schematic drawings assist in understanding cooling tower systems by providing simplified, symbolic representations of the system’s components and their connections. These drawings highlight the flow of water, air, and energy through the cooling tower, illustrating how each element interacts to achieve the desired cooling effect.

By focusing on the functional aspects rather than detailed physical attributes, schematic drawings help engineers and technicians grasp the overall system operation, identify key components, and understand the relationships between different parts. They are particularly useful for troubleshooting, maintenance, and training, as they offer a clear and concise overview of the system’s operation. Schematic drawings play a vital role in effective system design, analysis, and communication, ensuring that all stakeholders have a common understanding of the cooling tower’s functionality.

When should you review the electrical scope of works for cooling tower installations?

Review the electrical scope of works for cooling tower installations during the design and planning stages to ensure that all electrical requirements and specifications are clearly defined and integrated into the project. The electrical scope of works outlines the electrical components, wiring, control systems, and power supply requirements necessary for the cooling tower’s operation.

During the design phase, reviewing the electrical scope helps identify the power needs, control strategies, and safety measures required for the installation. This ensures that the electrical infrastructure is adequately designed and that all components are compatible and properly coordinated. Reviewing the electrical scope during planning also helps prevent potential issues during installation and commissioning, ensuring a smooth and efficient process. Regular review and coordination with electrical engineers and contractors are essential for successful cooling tower installations.

Where can you find detailed installation checklists for cooling towers?

Detailed installation checklists for cooling towers can be found in manufacturers’ installation manuals, which provide step-by-step guidelines for proper assembly and integration. These manuals include comprehensive checklists that cover all aspects of the installation process, from site preparation and foundation requirements to component assembly, piping connections, and electrical wiring.

Industry associations and organizations such as ASHRAE (https://ashrae.org/) and ISHRAE (https://ishrae.in/) also offer installation guides and checklists as part of their best practice resources. Consulting these checklists ensures that all critical steps are followed, reducing the risk of errors and ensuring a successful installation. Detailed installation checklists help maintain consistency, quality, and compliance, leading to reliable and efficient cooling tower operations.

What supporting details are necessary for the proper installation of a cooling tower?

Proper installation of a cooling tower requires several supporting details to ensure optimal performance and reliability. Key supporting details include:

- Site Preparation: Ensure a stable and level foundation, adequate drainage, and sufficient space for the tower and associated equipment.

- Structural Support: Verify that the structure can support the weight and dynamic loads of the cooling tower.

- Piping and Valves: Install appropriate piping, valves, and connections to facilitate water flow and system integration.

- Electrical Connections: Ensure proper wiring, control systems, and power supply for safe and efficient operation.

- Water Treatment: Implement water treatment measures to prevent scaling, corrosion, and biological growth.

- Access and Safety: Provide access points for maintenance and safety features such as ladders, platforms, and safety railings.

These supporting details are essential for a successful installation, ensuring that the cooling tower operates efficiently and safely.

Why is regular maintenance crucial for cooling tower performance?

Regular maintenance is crucial for cooling tower performance because it ensures the system operates efficiently, reliably, and safely. Maintenance activities include cleaning, inspecting, and servicing components such as fill media, fans, pumps, and drift eliminators. Regular cleaning prevents the buildup of scale, algae, and debris, which can obstruct water flow and reduce heat transfer efficiency.

Inspection and servicing help identify and address potential issues such as corrosion, leaks, and mechanical wear before they escalate into major problems. Proper maintenance also extends the lifespan of the cooling tower, reduces energy consumption, and minimizes downtime. By maintaining optimal performance, regular maintenance helps prevent costly repairs and replacements, ensuring continuous and effective cooling tower operation. Implementing a comprehensive maintenance program is essential for achieving long-term reliability and efficiency.

How can troubleshooting and diagnostics enhance cooling tower efficiency?

Troubleshooting and diagnostics enhance cooling tower efficiency by identifying and resolving operational issues that can compromise performance. Diagnostic tools and techniques, such as thermal imaging, vibration analysis, and water quality testing, help detect problems such as blockages, imbalances, and chemical imbalances that can affect heat transfer and energy efficiency.

Effective troubleshooting involves systematically analyzing the system to pinpoint the root causes of issues, whether they are mechanical, electrical, or chemical. By addressing these issues promptly, maintenance teams can restore optimal performance, prevent further damage, and reduce energy consumption. Regular diagnostics and proactive troubleshooting ensure that the cooling tower operates at peak efficiency, maintaining the desired cooling capacity and extending the system’s lifespan. These practices are essential for achieving energy savings and reliable operation.

What are the environmental impacts associated with cooling tower operations?

Cooling tower operations can have several environmental impacts, including water consumption, chemical usage, and drift emissions. Cooling towers use large volumes of water for evaporative cooling, which can strain local water resources, especially in arid regions. Implementing water conservation measures, such as recycling and efficient water management practices, can mitigate this impact.

Chemical usage for water treatment can lead to the discharge of harmful substances into the environment if not properly managed. Using environmentally friendly treatment methods and adhering to regulatory guidelines can minimize chemical pollution. Drift emissions, or the release of water droplets into the atmosphere, can carry dissolved chemicals and contaminants, impacting air and water quality. Employing efficient drift eliminators can reduce drift loss and its associated environmental effects. By addressing these impacts, cooling tower operations can be more sustainable and environmentally responsible.

FAQ

What is the purpose of a cooling tower?

A cooling tower removes heat from water by evaporative cooling, reducing the water temperature for reuse in HVAC and industrial processes. It dissipates heat into the atmosphere, ensuring efficient system operation.

What is a cooling tower vs chiller?

A cooling tower uses evaporative cooling to lower water temperature, while a chiller uses refrigeration cycles to cool water. Cooling towers are often part of chiller systems, enhancing their efficiency.

What is the difference between cooling tower and HVAC?

HVAC systems provide heating, ventilation, and air conditioning for buildings. A cooling tower is a component within HVAC systems, specifically used to dissipate heat from the water used in cooling processes.

What are the four types of cooling tower?

The four main types of cooling towers are crossflow, counterflow, forced draft, and induced draft. Each type has unique design features and operational principles, suited for different applications.

Cooling tower name

Common cooling tower names include crossflow, counterflow, induced draft, and forced draft towers. These names reflect the design and airflow direction within the tower.

Cooling tower pdf

Cooling tower PDFs provide detailed information on specifications, performance data, and installation guidelines. Manufacturers and industry associations often offer these resources for reference and education.

Cooling tower working principle

Cooling towers work on the principle of evaporative cooling, where water is cooled by evaporation as it circulates through the tower. Airflow aids evaporation, dissipating heat and reducing water temperature.

Cooling tower in power plant

In power plants, cooling towers dissipate heat from the steam used in electricity generation. They condense steam back into water, ensuring continuous and efficient power production.

Cooling tower diagram

A cooling tower diagram illustrates the components and flow paths within the tower, including water distribution, fill media, fans, and drift eliminators. It helps visualize the cooling process and system layout.

Water cooling tower

A water cooling tower is a structure that removes heat from water through evaporation. It is widely used in HVAC systems, industrial processes, and power plants to maintain efficient cooling and temperature control.

Types of cooling tower

Types of cooling towers include crossflow, counterflow, induced draft, forced draft, and hybrid towers. Each type offers unique advantages and is chosen based on specific cooling needs and environmental conditions.

Cooling tower price

Cooling tower prices vary based on size, type, materials, and additional features. Costs range from a few thousand to several hundred thousand dollars, depending on the complexity and capacity requirements.

Conclusion

Cooling towers play a vital role in HVAC and industrial systems, providing efficient heat dissipation and enhancing system performance. By understanding their types, specifications, and maintenance requirements, engineers can select and manage cooling towers effectively, ensuring optimal operation and sustainability. Regular maintenance, compliance with codes and standards, and proactive troubleshooting are essential for achieving long-term efficiency and reliability. As environmental concerns grow, adopting sustainable practices and technologies in cooling tower operations becomes increasingly important, ensuring responsible resource use and minimal environmental impact.

Related Links

For more information on related topics, you can visit the following links:

HVAC Related Affiliated Products

About The Author

As the Founder of HVAC Technocrats, I bring over 18 years of experience as a Mechanical Engineer specializing in HVAC (Central Air-conditioning) for commercial, cleanrooms, data centers, and Petrochemical industries. Throughout my career, I’ve held pivotal roles at companies like TATA Consulting Engineers, MW Zander (for Cleanroom solutions), Bluestar Malaysia, and ETA in Dubai. I’ve managed international HVAC projects and gained valuable exposure in dynamic markets like Dubai and Saudi Arabia. With a passion for excellence and a commitment to innovative solutions, I specialize in designing Class 10K & 100K Cleanrooms for various industries. Connect with me to explore collaborations in HVAC design, project sales, and consultancy.

Disclaimer: The pictures used are for illustrative purposes only. They may not depict actual products or situations and are meant for educational purposes. Actual products, situations, or outcomes may differ.